- Joined

- Mar 26, 2018

- Messages

- 2,724

Be warned that if you go with ballscrews, you really won't be able to use the mill manually very well. Cutting forces will move the axis you aren't using unless it is locked. On top of that, the motors will cog making it harder to spin by hand and the faster you spin them, the more they'll fight you as you power up the stepper drive with the back EMF.

I had handwheels on mine for a while and the only time I used them was to move the table out of my way when the machine was turned off.

You'd be better off planning on setting up a nice pendant.

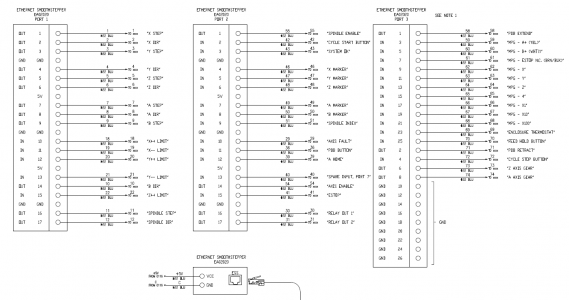

Good use for your 3rd port on the ESS. Wireless ones are OK, but I would never trust a wireless Estop.

I had handwheels on mine for a while and the only time I used them was to move the table out of my way when the machine was turned off.

You'd be better off planning on setting up a nice pendant.

Universal 4 Axis CNC Handwheel MPG Pendant w/ E-Stop For CNC Router Machine【USA】 | eBay

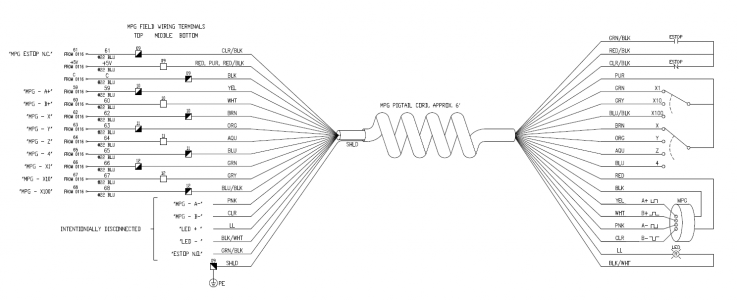

X,Y,Z,4th axis selector switch. Required 5V+, 150mA, power for MPG. Wiring:User can wire this unit to the CNC system with easy. LED indicator. TTL output, drive capability +-20mA;. Magnetic base holder can place anywhere on the machine steel surface.

www.ebay.com

Good use for your 3rd port on the ESS. Wireless ones are OK, but I would never trust a wireless Estop.