- Joined

- Sep 8, 2019

- Messages

- 4,392

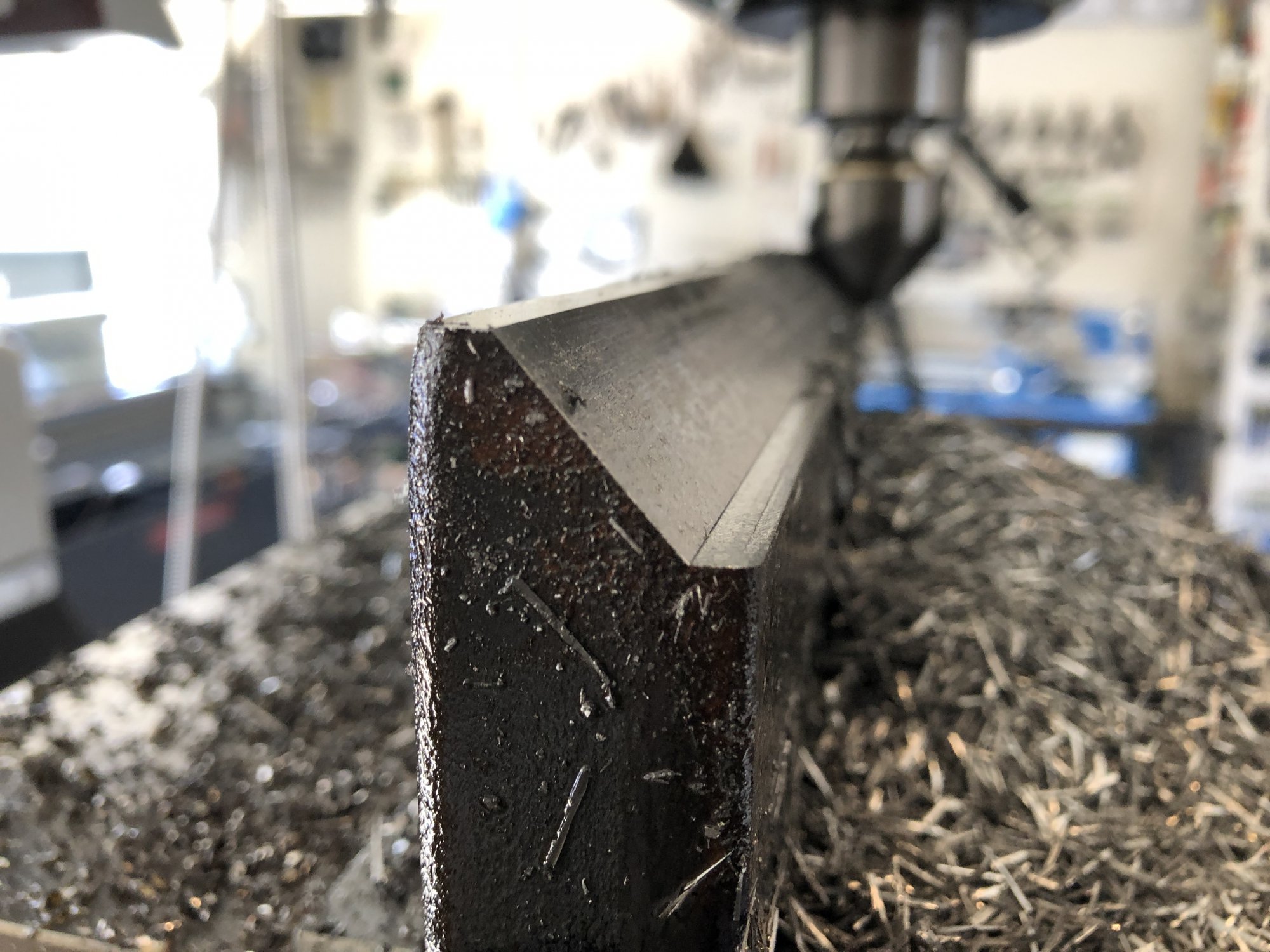

Now I just noticed that I am cutting this angle at 49°, while I wanted 41°. Something to think about while I am at work today.

I think I figured it out. I need to *lay the 1”plate down on parallels*, and cut from the top.

I think I figured it out. I need to *lay the 1”plate down on parallels*, and cut from the top.

Last edited: