- Joined

- Sep 8, 2019

- Messages

- 4,392

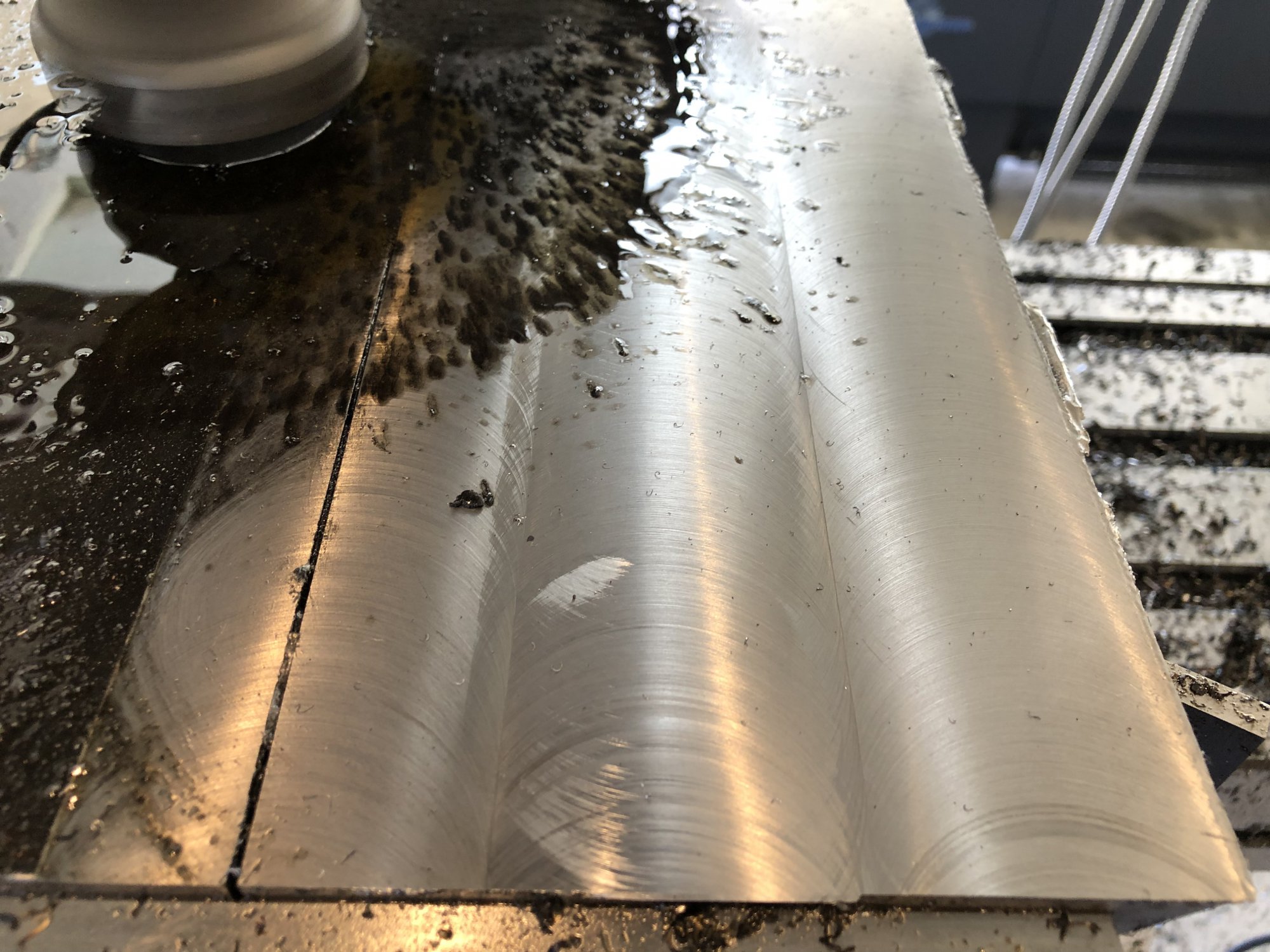

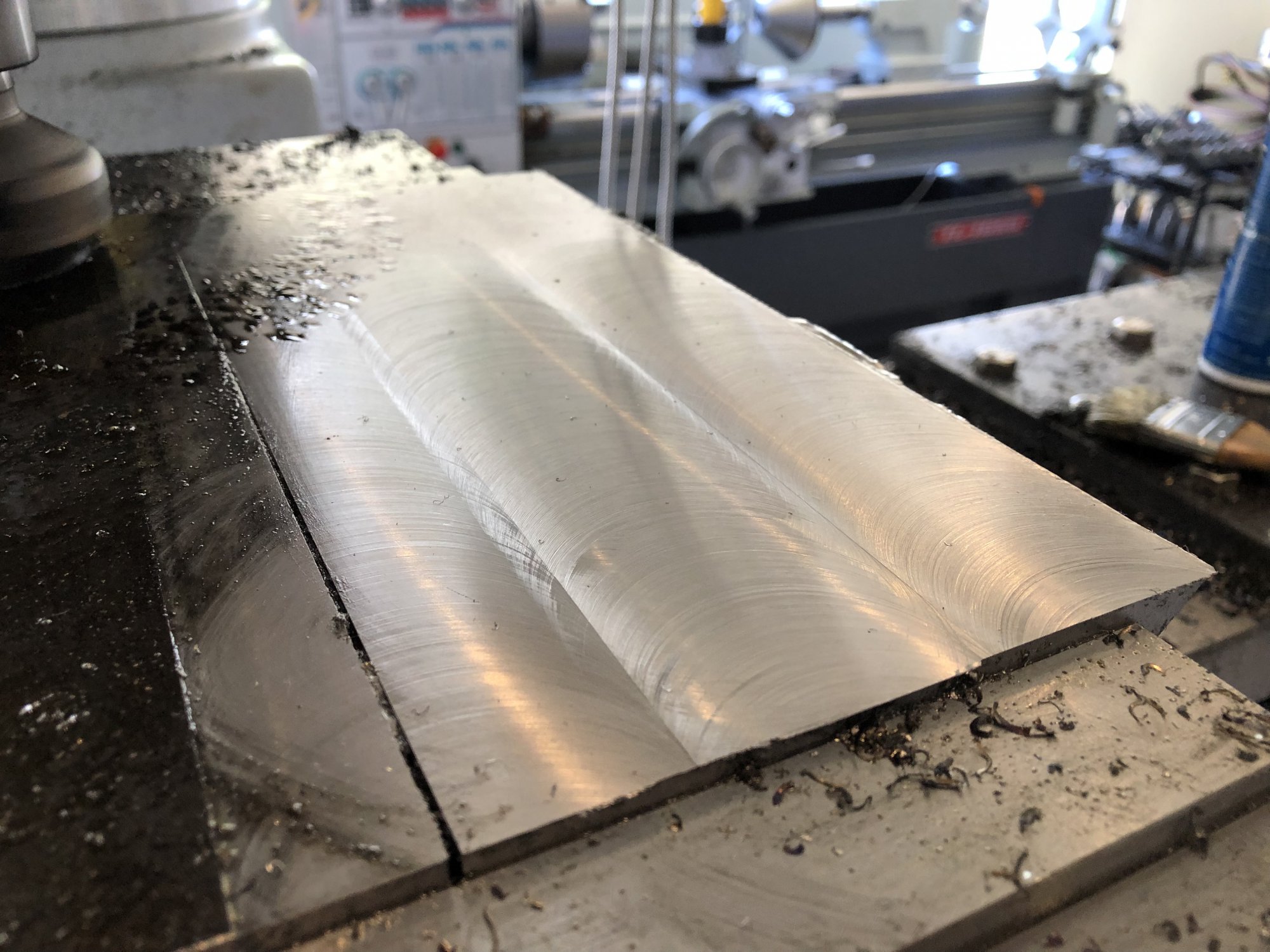

Here is the surface finish that I am getting, trying as hard as I can. No matter how you look at it, this is not good enough.

Please identify your specific face mill and the inserts you are using. Without this info, it‘s hard to know how to help. If you’re using the Glacern FM45 with the General Purpose Kolroy inserts for steel (SECA34-PC3500), l would be running that cutter at 550 RPM on 1018 steel with a Feed rate of about 12 IPM. It looks to me like you’re recutting some chips, so set up some air to blow them off the material if surface finish is your goal and speed up your feed rates. Where is the vibration? Head? Ram? Whole machine? Do you have the knee and ram dovetail locks engaged? If your mill is rocking on it’s feet, that can telegraph through to your surface finish. Did you re-tram your mill after the crash?Here is the surface finish that I am getting, trying as hard as I can. No matter how you look at it, this is not good enough.

Thank you for helping, David. The facing mill is indeed the Glacern 2” integral R8 shank. See below for a picture of the inserts that I’m using.Please identify your specific face mill and the inserts you are using. Without this info, it‘s hard to know how to help. If you’re using the Glacern FM45 with the General Purpose Kolroy inserts for steel (SECA34-PC3500), l would be running that cutter at 550 RPM on 1018 steel with a Feed rate of about 12 IPM. It looks to me like you’re recutting some chips, so set up some air to blow them off the material if surface finish is your goal and speed up your feed rates. Where is the vibration? Head? Ram? Whole machine? Do you have the knee and ram dovetail locks engaged? If your mill is rocking on it’s feet, that can telegraph through to your surface finish. Did you re-tram your mill after the crash?

@JRaut post your link reference please. I'm looking at the following (Speeds tab), and don't see recommendations for his KC510M grade with steel, but the closest thing to it, has SFM's more in the 500-900 range. I have a face mill similar to his, and there's no way I'd run it at the speed you mention on steel - aluminum yes, but not steel.A quick check of Kennametal's website suggests you're going WAYYYY too slow in both speed and feed for those inserts. Unless I'm running the numbers wrong...

Kennametal says that a starting point should be:

- 1450 - 1780SFM == ~2800-3400 RPM for a 2" diameter cutter

- 0.003 - 0.021 inches per tooth == 36 - 250 inches per minute for a 4-insert cutter at 3000 RPM

That's probably near the top of your RPM range, and about as fast as you can possibly crank the handle.

Scary business.....