-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Greg's Logan 820 Restoration

- Thread starter gjmontll

- Start date

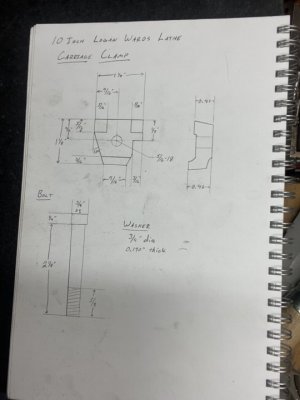

Take a look back in this long thread to the posts from 09 - 14 Aug 2013, as we discuss this very issue. My simple lock has worked out fine )and I never did make the fancy bolt.)Does anyone have the specifications for the small carriage lock plate on a Logan 10 or 11 lathe. I lost mine in transit.

..

- Joined

- Jan 19, 2012

- Messages

- 177

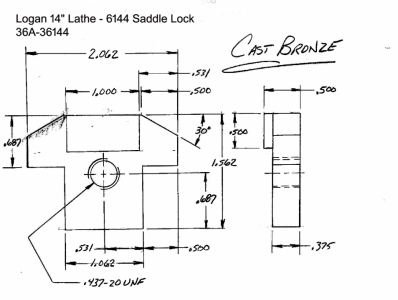

Don't know if there the same but this is for a 14" Logan.Take a look back in this long thread to the posts from 09 - 14 Aug 2013, as we discuss this very issue. My simple lock has worked out fine )and I never did make the fancy bolt.)

Attachments

Thanks .I had read your post prior to uploading mine. I don't have the saddle off the ways so as to take actual measuements. I was hoping to avoid the disassembly. Did you draw out the specs or jut shoot from the hip and make things fit?Take a look back in this long thread to the posts from 09 - 14 Aug 2013, as we discuss this very issue. My simple lock has worked out fine )and I never did make the fancy bolt.)

gjmontll,Don't know if there the same but this is for a 14" Logan.

Thanks for the drawing with specifications.

Unfortunately the 9 and 10" lathes us a different lock nut made of, I think, cast iron.

I did sharpen up you line sketch and I'm putting it with this response.

Steve

TJ,

Thank you so much for your diagram and measurements. The original cost of the clamping nut was about 20 cents. Theses days Logan is asking over $21 and another $21 for shipping.

With your help I'll make it myself.

Steve

- Joined

- May 9, 2022

- Messages

- 8

Hi Greg, I have this self same lathe! A few questions for you sir. Where is the serial number found? I need help with manuals and a parts book, so where did you find yours? Mine was dismantled for shipping, and if you have fotos of how to mount the motor assembly I would be extremely grateful to have them so I can get this lovely lady working again. Thanks in advance. RobbIn February 2013, I bought a Logan 820. Serial Number is 24157 (Made in 1944, it would be be interesting to know its history). A good project for my upcoming retirement!

This Logan was to be an upgrade from the Atlas 618 I've had for the past 4 years and that served as my entry into this home machining hobby. The 820 was operational, but clearly in need of some refurbishing.

In April I retired. First, I needed to get the Atlas repaired and sold to make some room in the garage. Had to move the Atlas every time I needed to get to my X2 minimill.

Preparatory Logan work: Get AXA toolholders for the Logan, the parts diagram/list, a face plate, threading dial, and other assorted tooling. I made chuck keys for the 8" 4-jaw chuck, and then overhauled the chuck, and overhauled the 3-jaw chuck. (Both interesting exercises in their own righ!)

Finally, I used the Logan to make new cross slide and compound slide crank handles for the Atlas. Now it's sold, gone, and I've got room to tackle the Logan.

Here is the starting point, prior to whatever degree of restoration I get done.

View attachment 57587

Some major issues I hope to remedy:

And then there are many minor issues, other minor missing parts. I'm sure I'll be assembling a shopping list or two for Logan Actuator.

- QCGB: left selector arm is almost frozen. With the aid of a brass rod and a mallet, it does shift and appears to work okay. Hard to read the gear chart, if it doesn't clean up then I'll get one from Logan Actuator.

- Headstock: Backgear lever missing the detent mechanism. Oil leaking on the left hand spindle pulley. I'm not sure if it's leaking from the "Oil" setscrew or the other setscrew, and not sure if the setscrews are quite the right length and type.

- Apron and saddle: Apron leaks oil. I'm not sure when the lathe was lasted oiled, but it didn't appear to be very recently. Hopefully the prior owner(s) didn't do too much damage. There is no carriage lock, so I plan to make one or order one. Handwheel bushing is very worn and will be replaced. I assume that several other bushings in the apron are also worn. We'll see when I tear it down. Power feeds are in working condition; I'm not expecting major problems.

- Appearance: Ugly paint. The blue on the belt cover, legs, and tailstock is not too bad, but the headstock, bed, QCGB, apron/saddle, and tray need to be restored. I guess I'll make them blue to match.

- Leveling:The garage floor is not level. I plan to get/make some jackscrew-type levelers to put under the feet.

And now it's July, Stay tuned as I dig in. I welcome your feedback, ideas, hints, comments of any kind.

Greg

View attachment 57587

Robb,

I assume you just acquired your 820, I hope it will do the job for you, (whatever that might be.) You may have already read through my long series of postings in this thread. Some of it may certainly be useful and I'd be glad to answer any other questions. I guess a lot depends on the condition of your specimen.

Now to your specific questions:

The serial number is on the front right upper corner of the bed, just above the bushing for the end of the lead screw. You will need to know the s/n because in many cases, correct part numbers are serial number dependent.

The essential document you're looking for is the Operators Instructions Parts List for the Model 800 Series.

Here are a bunch of ways to contact Logan:

About your "motor mount assembly" ... I don't know exactly how disassembled your lathe is, but I had the whole drive unit/motor mount/pegleg completely torn down. I even disassembled the motor to examine, clean, and lubricate it. You should read my postings starting on "page 7" of this thread (start with my Dec 15, 2013 posting about making leveling feet, since that affected the pegleg too.) Maybe my photos (along with the parts catalog's drawings will answer your questions. My lathe sits up close to a shelving unit behind it, with a workbench close on the right and my mill close on the left. So trying to get any good photos now is not easy, but I'll try to help you as I can.

I hope you'll inform us as you progress. Advice from this forum was certainly vital in my efforts.

Good luck,

Greg

I assume you just acquired your 820, I hope it will do the job for you, (whatever that might be.) You may have already read through my long series of postings in this thread. Some of it may certainly be useful and I'd be glad to answer any other questions. I guess a lot depends on the condition of your specimen.

Now to your specific questions:

The serial number is on the front right upper corner of the bed, just above the bushing for the end of the lead screw. You will need to know the s/n because in many cases, correct part numbers are serial number dependent.

The essential document you're looking for is the Operators Instructions Parts List for the Model 800 Series.

Here are a bunch of ways to contact Logan:

Mailing address: Logan Actuator Company, 550 Chippewa Rd, Harvard, IL 60033-2372

Telephone: 815.943.6755, Fax 815.943.6755

Web: http://www.loganact.com

Email: sales@loganact.com

There is also a useful email-based "Logan Lathe Users Group." It is run by Scott Logan, the president of the company.About your "motor mount assembly" ... I don't know exactly how disassembled your lathe is, but I had the whole drive unit/motor mount/pegleg completely torn down. I even disassembled the motor to examine, clean, and lubricate it. You should read my postings starting on "page 7" of this thread (start with my Dec 15, 2013 posting about making leveling feet, since that affected the pegleg too.) Maybe my photos (along with the parts catalog's drawings will answer your questions. My lathe sits up close to a shelving unit behind it, with a workbench close on the right and my mill close on the left. So trying to get any good photos now is not easy, but I'll try to help you as I can.

I hope you'll inform us as you progress. Advice from this forum was certainly vital in my efforts.

Good luck,

Greg

- Joined

- May 9, 2022

- Messages

- 8

Hi Greg, you are giving me renewed hope for the revival an use of this little gem. Many many thanks.Robb,

I assume you just acquired your 820, I hope it will do the job for you, (whatever that might be.) You may have already read through my long series of postings in this thread. Some of it may certainly be useful and I'd be glad to answer any other questions. I guess a lot depends on the condition of your specimen.

Now to your specific questions:

The serial number is on the front right upper corner of the bed, just above the bushing for the end of the lead screw. You will need to know the s/n because in many cases, correct part numbers are serial number dependent.

The essential document you're looking for is the Operators Instructions Parts List for the Model 800 Series.

Here are a bunch of ways to contact Logan:

Mailing address: Logan Actuator Company, 550 Chippewa Rd, Harvard, IL 60033-2372Telephone: 815.943.6755, Fax 815.943.6755Web: http://www.loganact.comEmail: sales@loganact.comThere is also a useful email-based "Logan Lathe Users Group." It is run by Scott Logan, the president of the company.

About your "motor mount assembly" ... I don't know exactly how disassembled your lathe is, but I had the whole drive unit/motor mount/pegleg completely torn down. I even disassembled the motor to examine, clean, and lubricate it. You should read my postings starting on "page 7" of this thread (start with my Dec 15, 2013 posting about making leveling feet, since that affected the pegleg too.) Maybe my photos (along with the parts catalog's drawings will answer your questions. My lathe sits up close to a shelving unit behind it, with a workbench close on the right and my mill close on the left. So trying to get any good photos now is not easy, but I'll try to help you as I can.

I hope you'll inform us as you progress. Advice from this forum was certainly vital in my efforts.

Good luck,

Greg

I did order the manual and parts book from Logan. Their site sucks (my opinion).

Continued reading and rereading of your posts are deemed ESSENTIAL! for me. I have no mill at the

moment, but found an Index brand knee mill in very good shape. I restore antique bikes so the use would

be small for that.

All the best, Robb