- Joined

- Mar 25, 2013

- Messages

- 4,645

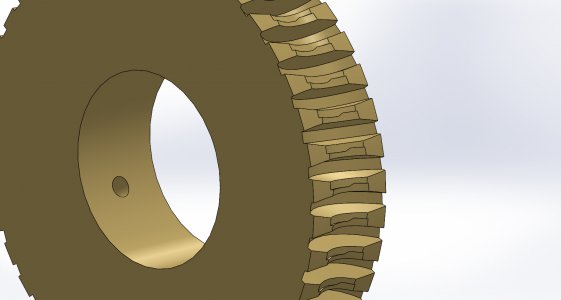

I have a ton of yellow mystery brass for casting that I will likely never use. Would a cast brass worm gear blank be good? Most of the brass is probably 60-70% zinc. I could add copper. Cast blanks would likely have small casting defects that we would have to accept.

Robert

Robert