- Joined

- Aug 3, 2017

- Messages

- 2,437

Not sure what you mean by a starter cut, but I sorta have an idea?

It is a pretty deep tapped hole as well, and 10-32! Luckily it's aluminum otherwise I'd break half of my tries

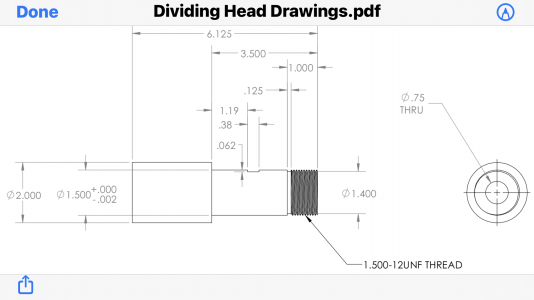

Also, flyingfool: the driven gear seems to have lost its center hole dimension. It's 1.500, right? I went to look for tolerance and didn't see it.

It is a pretty deep tapped hole as well, and 10-32! Luckily it's aluminum otherwise I'd break half of my tries

Also, flyingfool: the driven gear seems to have lost its center hole dimension. It's 1.500, right? I went to look for tolerance and didn't see it.