-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Guidance on buying a G&E shaper

- Thread starter Cooped_Up

- Start date

- Joined

- Nov 26, 2015

- Messages

- 4,772

That was their slogan up until the 30's I think. After that they started calling them heavy duty.also,there is a tag that says high duty, does that mean its a heavy-duty model? like it can take meatier bites...

okay, well that's good to know, ill take it easy and I don't think I could possibly break the thing. all I know is I put it in a trailer rated for 3000 pounds and it pushed it. I have heard some similar length stroke shapers weigh mush less so I figured that meant its good at big chipsThat was their slogan up until the 30's I think. After that they started calling them heavy duty.

- Joined

- May 10, 2012

- Messages

- 995

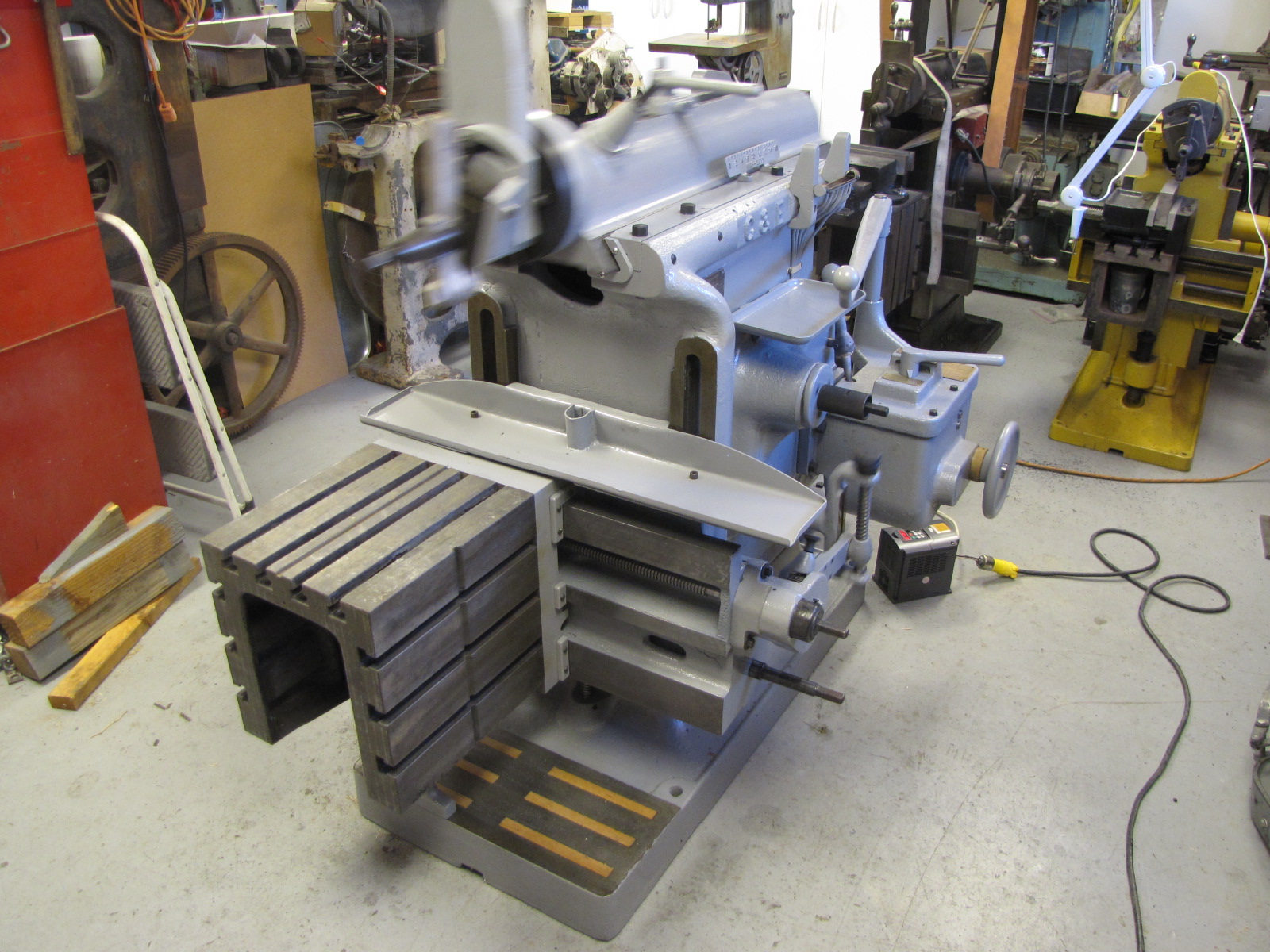

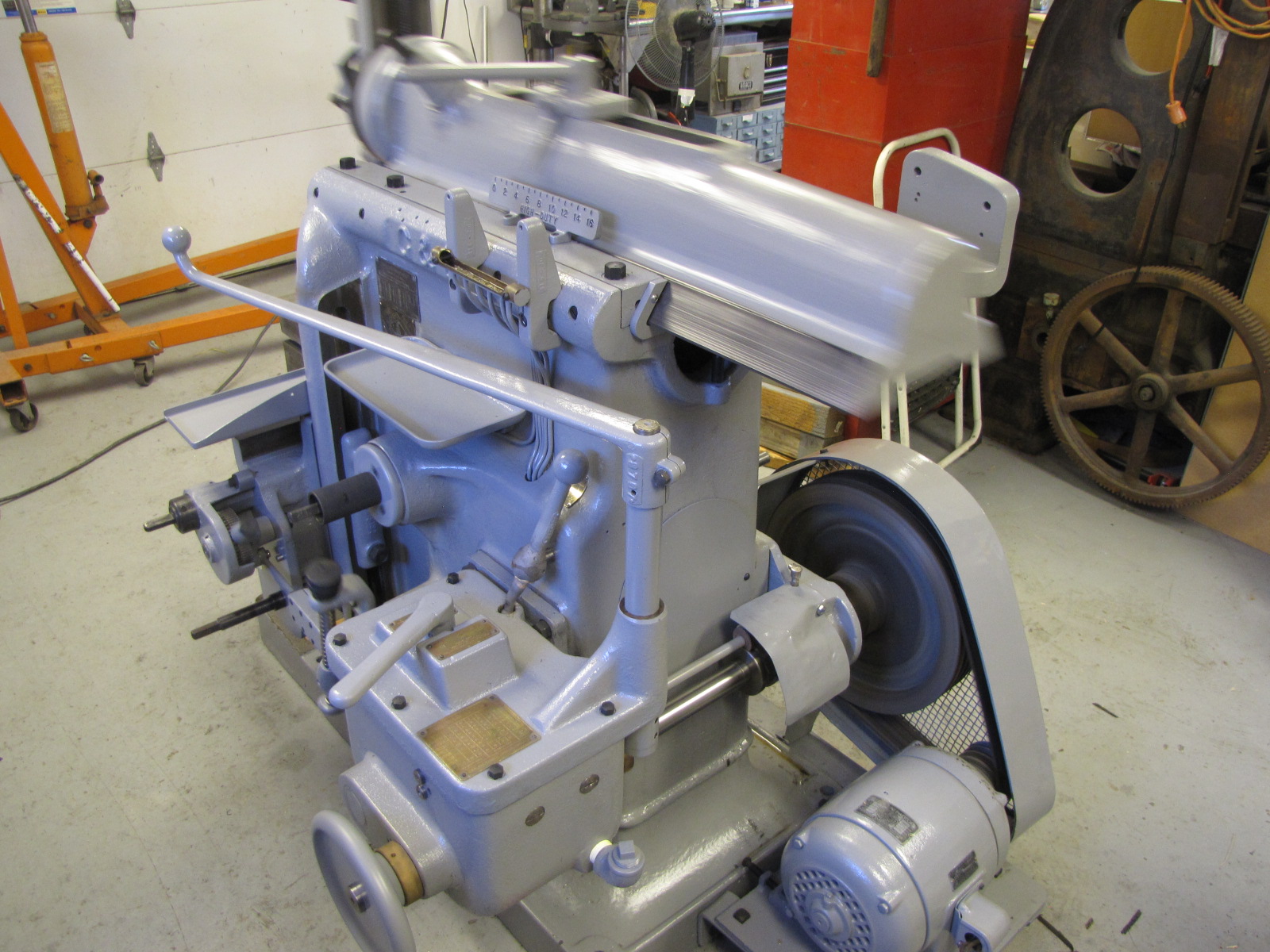

I'm pretty sure that broken handle is for the clutch, which is inside that housing by the grearbox. Hi-Duty was kind of just a brand name, they did have two versions, a production version and a toolroom version, the main difference being that the toolroom version had finer feed capability than the production one. That shaper is set up different than mine, the motor drives the clutch and pulley on the other side and the shaft comes in from the left side of the gearbox, instead of the right like this one. That what makes me think this one is a bit older than mine. Or maybe they had options on which side of the machine the drive came on, who knows. Good luck, and if you tear it down completely, make sure you use a hoist to get the crank back in, don't try to do it by hand. Mine's nickname is "Old Thumb Crusher". Here's some pics of it.

You have a very nice machine! I don't think I have enough patience to do a nice restoration on mine. I'm thinking get the old paint off and maybe if it needs it do a little paint work. And if I find any problems along the way I will address themI'm pretty sure that broken handle is for the clutch, which is inside that housing by the grearbox. Hi-Duty was kind of just a brand name, they did have two versions, a production version and a toolroom version, the main difference being that the toolroom version had finer feed capability than the production one. That shaper is set up different than mine, the motor drives the clutch and pulley on the other side and the shaft comes in from the left side of the gearbox, instead of the right like this one. That what makes me think this one is a bit older than mine. Or maybe they had options on which side of the machine the drive came on, who knows. Good luck, and if you tear it down completely, make sure you use a hoist to get the crank back in, don't try to do it by hand. Mine's nickname is "Old Thumb Crusher". Here's some pics of it.

View attachment 334648

View attachment 334649

View attachment 334650

- Joined

- May 10, 2012

- Messages

- 995

You have a very nice machine! I don't think I have enough patience to do a nice restoration on mine. I'm thinking get the old paint off and maybe if it needs it do a little paint work. And if I find any problems along the way I will address them

Mine was from a school, so it had been abused. It also sat outside for about 3 years before I restored it. Luckily outside in the desert mostly means there is sand everywhere, the rust was easily removed. On mine the bellcrank for the clutch was broken, one of the handles was broken, 3 of the 4 way wipers were ruined, the stroke adjustment rod was broken, the vise was worn out and abused and the bevel gears that raise and lower the table were stripped. I tore it down completely, made or repaired parts for it (there is a thread on here of the bevel gear repair), cleaned and painted everything. I think it took about 3 months mostly working on it on the weekends. That time also includes building that rolling stand that it's on, so the machine restoration didn't take that long.

Well I got it off the trailer finally, and I even got power run to it. After oiling the crap out of everything i got it going under its own power and it seems to be in running order, it is a little loud so I'll probably just cover the loud parts in some grease.

Attachments

- Joined

- Sep 2, 2013

- Messages

- 5,099

I know it's tough to go slow at your age, but take some time to get to really know the workings of the machine. Especially make sure that the main ways are getting oil. Congrats on your purchase, it can be a very useful peice of equipment. Cheers, Mike

Well they only get oil when I give them oil and like I said I oiled everything and then some. There are ports to oil the ram, 2 on each side. I oiled almost every shaft, gear, and bushing. I know how the machine functions but not all of the nitty gritty. I definitely am not going slow but I have had plenty of time learning about shapers and how they workI know it's tough to go slow at your age, but take some time to get to really know the workings of the machine. Especially make sure that the main ways are getting oil. Congrats on your purchase, it can be a very useful peice of equipment. Cheers, Mike