@macardoso : Thank you for the list. In going through it, I already check out OK on much of the stuff.

Re: Measuring stuff

I use the cheaper Chinese with the South Bend Lathe for getting "nearly there", or for non-critical sizing.

When want real precision, I get out the better kit.

I have more quality calipers than most could need. Like many, I have one of the low-cost eBay variety, and the "Silverline" brand is handy, with the big digits. I have taken it apart and "modified" it a little, to stone outer sharp edges, tighten up the mechanism, etc. It's pretty good for the price. The number it delivers can be this way or that, depending on thumb pressure by about 0.0005". It disagrees with the gauge block by about 0.0007, when it is open to 50mm.

Then comes the "good" ones. I have the iGaging OriginCal. This one is an "absolute" type like Mitutoyo. You can zip it about, and close up with any pressure you like, it always knows where it is, and it always zeros. The only feature it does not have is auto-turn-off, but even if one forgets, it seems not to matter much. It does not chew batteries. I had a quick inventory..

-->

iGaging OriginCal - IP54

The Mitutoyos are the dial caliper and the 25mm metric 0.001mm.

The gauge blocks are Bowers Metrology Cal Lab BS 4311 Grade 1

The 300mm bigger caliper is a Kanon in both inches and cm.

The Electronic Digitals are 0-26mm and 25-52mm Chinese, and checked out on the gauge blocks.

The little Moore & Wright is one from the complete set of internal micrometers I refurbished and calibrated.

There is also (not shown) two vernier height gauges with carbide wedge scribes, the three 0.02mm/m levels, various Rabone Chesterman rules, two sizes sine bar, a Chinese vernier protractor, a 2ft straight edge 1/4" thick x 1.5" wide with beveled one edge, and a 3ft (floppy) straight edge 1/16" thick x 2" wide.

- - - - - - - - - - - - - - - - - - - -

2. The Vise - there may be discussion here!

Or "Vice" as in the British dictionary, and they don't mean decadent deviance!

This I still have yet to get, and here we run into all sorts of choices. The advice from

@Mitch Alsup is to not use the type with a rotational base, not the type that can tilt up at a settable angle, or worse - both! Flat down hard on the T-slots is stiffest. I am not sure my relatively smaller mill would shove hard enough to make it significant.

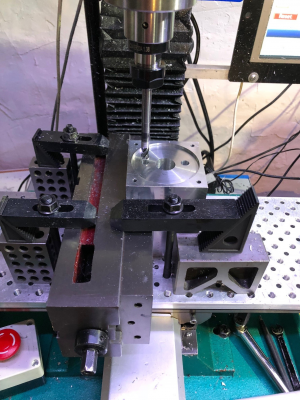

We may have to have experts discuss these for newbies. I exclude simple hand vises, and with small 2-axis cross slides as used on drill presses.

There are several sorts:

a) As 100mm (4") vise on vertical axle rotation, with 1 degrees graduations. Sometimes undeservedly referred to as "precision".

Can be had for about

$60 to $70 (£50 ish)

- - - - - - - - - - - - - - - - - - - - - -

b) There is a type called

"self centering". It has half the thread right-handed, and the other half left-handed. This example is a 3" (75mm) size.

Is that a handy feature? This one goes for

$87 (£65). Do we want a mill vise to do that?

- - - - - - - - - - - - - - - - - - - - - -

c) It can tilt in 2 axes. I guess this is the one

@Mitch Alsup meant was a bad choice!

- - - - - - - - - - - - - - - - - - - - - -

d) Is this "Precision"? Is it "Ultra-Precision"? It looks kinda swish. It might also be Uber-'n-Mega expensive!

This one is from the Orange Vise Co. Don't know the price. I think you probably need a lawyer and an appointment to find out!

- - - - - - - - - - - - - - - - - - - - - -

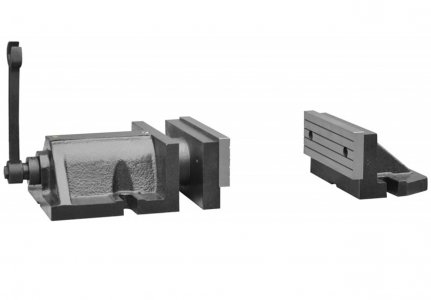

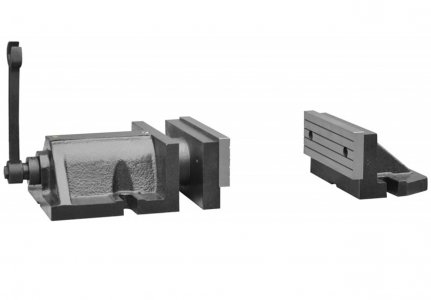

e) There is the 2-part, so-called "infinite vise". This one is

$215 (£160.71) from CORMAK. I guess it lets you set for wide stuff. Given the cost, I guess it is a useful feature, but experts please comment.

- - - - - - - - - - - - - - - - - - - - - -

f) There is the one-axis-only tilt. This one also from CORMAK for

$111.35 (£83.10)

- - - - - - - - - - - - - - - - - - - - - -

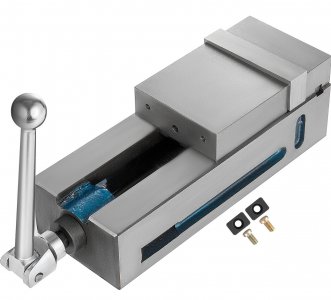

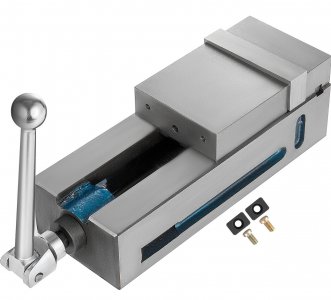

g) There are many that include the word "Precision" This one is a 4-inch from UK eBay -->

4" SuperLock Vise

This for

$91.72 (£68.45)

- - - - - - - - - - - - - - - - - - - - - -

This posting has got big enough already, and we are only on item #2 of the list from

@macardoso .

Please experts, comment freely about the goods, and bads of the above. I can sniff out the quality brands, and I am sure there are some that can be mentioned with confidence in supplying products you can trust. Do you have any that let you down? Have you ever refurbished one of these? What are things not to do? What is the deal with the removable handle looking a bit like something you would use to crank a 1940's Ford? Is that more convenient? Why do some 2nd-hand 4" and 6" mill vises ask prices well above these new ones/

Things I would like to know are .. are they always hardened? Do they have bearings? Does the thread shaft wear out? Do they always have gibs?

I will trawl choices on further kit in another posting.