- Joined

- May 27, 2016

- Messages

- 3,469

Thanks David.My vise ad'vice' is to get the best one can afford because it is the foundation of your work. While you may not be hogging off gobs of metal in a single pass, any inaccuracies will translate to the work.

Out of square jaws, jaws that lift when tightened all contribute to inaccurate work. And while I don't think you are sub-contracting for British Airways to make jet engine parts, parts that are out of square are just annoying.

I could not stomach the price of a 4" Kurt or Orange vise so I opted for a Glacern 4". It's as accurate as I can measure with my tenths indicator and finished very well.

I would not get anything that swivels or tilts.

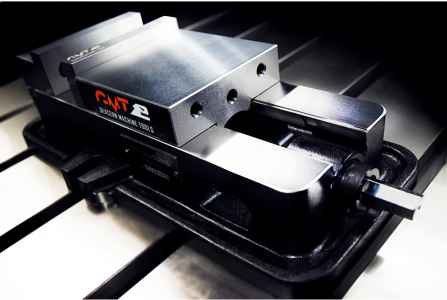

The tool makers style vises such as what Stefan Gotteswinter uses seems to be a smart choice for a small mill.

While I am not sure that it has a flat side that can allow it to be turned on it's side like in @macardoso 's picture, I provide the link to their site.

The standard vise is $349. Then there is a range of other options.

--> Glacern 4" Vise

The following are optional extras..

4-Inch Chomper Hard Jaws $149.99

4-Inch Hardened Vee Jaw $99.00

4-Inch Serrated Hard Jaws $139.99

4-inch Original Hard Jaws (Pair) $59.99 (I guess if you happen to accidently "mill" part of the vise.)

Soft Jaws - 4 Inch Aluminum $55.00

Extra Wide 6 AL Soft Jaws for 4" $99.00

Crank Handle for 4-inch Vise $29.00

These take the additionals to an art form. A "work stop" is $99.99.

This begs the questions. .

Why hardened jaws anyway?

Why soft jaws?

Why serrated jaws?

How hard are standard jaws? (Discovered the bed and jaw places are HRC 50)

I know this seems like I dig hard, but with almost every new thing I see, and every great reply I get, the mind finds a new question.

The thing that decided me on the vise style is that there is advantage in the design of the last of the set I posted. The same flat side type is seen in the crushingly expensive Orange Vise Co products) Clean sides that allow turning on it's side like in @macardoso 's picture.

I digress, but that too shows stuff to get the beginner curious. A slab of aluminium under with enough threaded holes to have wore out one's lifetime supply of that size tap!

Last edited: