- Joined

- Nov 27, 2012

- Messages

- 7,856

My PM1236 arrived last Friday, been looking it over.

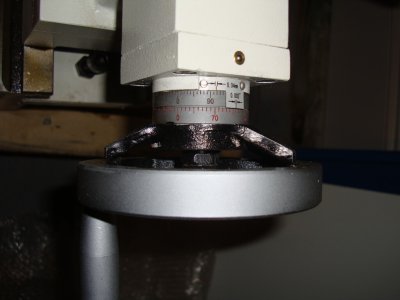

I discovered to my dismay that my machine is metric, metric compound and cross slide lead screws and a metric threading lead screw. Can someone confirm if these are metric or imperial. I have some literature that touts it having inch lead screws. What am I missing??????

Craig

I got your PM but I'll just answer here as it's pretty much the same....

If I may ask, what gives you the impression that you have metric leadscrews? My PM1236 is imperial. I have confirmed that my carriage leadscrew is 8 TPI, same as the Grizzly 12x36s.

I'm assuming you held a scale up to your leadscrew? How many teeth per inch do you have?

Another way to confirm is to single point a thread. Don't need to do a full thread of course, just a scratch pass. The threading dial & chart are only good for imperial threads & won't work for metric. Confirm you have the 24T gear up top & the 48T gear on bottom, then do a 16, 24, 32 (etc /8) TPI scratch pass (& check the thread pitch if you want), disengage the half nut, bring the carriage back & do another cut engaging the halfnut at any position. If you do have an 8 TPI leadscrew you can engage the halfnut at any point (threading dial does not matter) & still line up with the thread. If you do in fact have a metric leadscrew, chances are you won't line up on that first scratch pass.

Last edited: