- Joined

- Jun 20, 2022

- Messages

- 226

Most of the cheep starter fluids you buy at the hardware store are lucky if they have 30% etherI'm waiting on some John Deere 80% ether. I tried to get it to "pop" by priming the carb....no joy. But also no idea what % ether the cheap hardware store

Most of the cheep starter fluids you buy at the hardware store are lucky if they have 30% ether

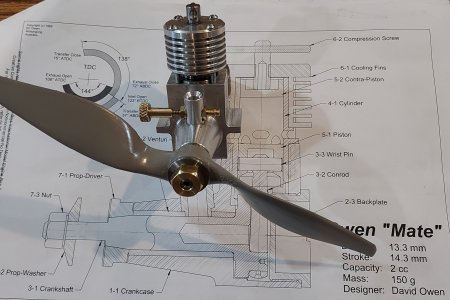

Great work on the engine

Cheers

Andrew