by the way i orders the mitotoyo caliber, and its on its way. So the gib will stay out till it comes home and i can start making measurements and then the others. I believe it will be a good project as i will need trapezoidal ways for other ideas too so being able to make the ways and gibs up to a certain quality might come very handy as a hobbyist machinist. always need fixture for stuff

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Info needed for installing/setting up pm940m

- Thread starter tim81

- Start date

@tim81

As said. Use the tables. Most threading is not critical. But the classes mentioned by @verbotenwhisky just tells you how tight you want the threads to be for the screw/bolt. If you want a tight thread then the hole size should be small.

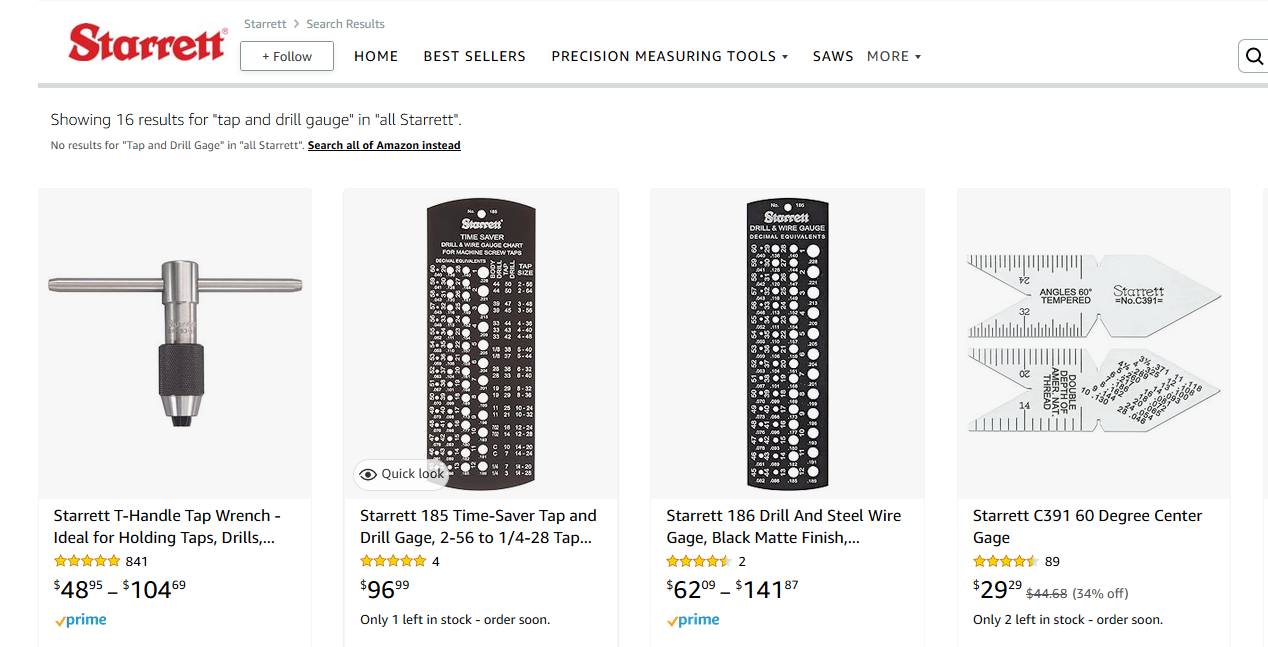

I purchased the Starrett 185 and have never regretted it. Mine is SS not black. You can get it on Amazon, or there are cheaper ones but they commonly have punched holes rather than precision cut holes and are not as accurate. I have those too, but always go back to the Starrett. I also have the 186, but I do not use it nearly as often as the drill gage. So you commonly cannot read the drill size on the side of the drill bit, but just slip it into the holes until you find where it just fits and you know the size. I also have a set of 50 and 60 degree centers (like the C391 shown) but by a less expensive supplier. There are tap handles which grip 4 sided tap and there are tap handles which grip 3 sided taps. You just need to know what kind of taps you have!

Drill bits. There are all kinds. I use tables like you posted. I do not usually buy my tools from HF unless I read their reviews and people think they are really good or it is simple and I can look at it and decide it is ok for the money. Much of their stuff is low grade. This is especially true if $$$$ are being spent. Many of their drill bits are soft and quickly wear out... ok for wood for a while. On the other hand I have had decent success with their carbide saw blades. Read the reviews. I needed a right angle drill. Bought one and it quickly broke. I then read the reviews, and guess what. All of them said they were junk. I read the reviews about an electrical hand planer and the reviews were good. I got it and it worked great. I have purchase a lot of drill bits from Grainger.com but a bit more expensive. There is a Grainger store in town. I order on line and then just pick it up. Saves on shipping. Sometimes they have them on close out sale, where they essentially give the parts away! Also, if the metric size is close and is on sale I sometime buy it and use it for the imperial tap hole! Just convert to inches or vise versa. Anyway, drill bits wear out and you have to buy more, so you tend to stock the size that you use. You cannot resharpen the smaller ones by hand anyway. Also not worth it. Taps wear out too. Use oil. I commonly tap at 1/4-20 and 6-32 so I tend to stock up on these drill bits and taps. There are all kinds of taps! You will just have to read about them. Common sizes in Imperial that I use: 10-32, 10-24, 8-32, 8-24, 6-32, 4-40.

As long as you are going to get these things you will also want to get a thread pitch gage. These allow you to measure the spacing of the threads on a bolt to determine what it is. They are cheap and very handy. Something like: https://www.amazon.com/ChgImposs-Im...&sprefix=thead+gage,industrial,77&sr=1-3&th=1

Vice: I purchased my vice from PM when I got the mill. The one I ordered was out of stock so they just gave me the next size up, 6 inches. It is a nice vice, but it weights in at ~95#. It is precise. I am now older and it is all I can do to lift it to the mill table! I am pretty sure the one I got was this or its equivalent. VISE-HAV-6in-SB-SUPER https://www.precisionmatthews.com/s...tra-high-precision-milling-vise-wswivel-base/ PM has always treated me right and so I shop with them. Besides they are in Pittsburgh too ... and only about 20 miles from me.

As said. Use the tables. Most threading is not critical. But the classes mentioned by @verbotenwhisky just tells you how tight you want the threads to be for the screw/bolt. If you want a tight thread then the hole size should be small.

I purchased the Starrett 185 and have never regretted it. Mine is SS not black. You can get it on Amazon, or there are cheaper ones but they commonly have punched holes rather than precision cut holes and are not as accurate. I have those too, but always go back to the Starrett. I also have the 186, but I do not use it nearly as often as the drill gage. So you commonly cannot read the drill size on the side of the drill bit, but just slip it into the holes until you find where it just fits and you know the size. I also have a set of 50 and 60 degree centers (like the C391 shown) but by a less expensive supplier. There are tap handles which grip 4 sided tap and there are tap handles which grip 3 sided taps. You just need to know what kind of taps you have!

Drill bits. There are all kinds. I use tables like you posted. I do not usually buy my tools from HF unless I read their reviews and people think they are really good or it is simple and I can look at it and decide it is ok for the money. Much of their stuff is low grade. This is especially true if $$$$ are being spent. Many of their drill bits are soft and quickly wear out... ok for wood for a while. On the other hand I have had decent success with their carbide saw blades. Read the reviews. I needed a right angle drill. Bought one and it quickly broke. I then read the reviews, and guess what. All of them said they were junk. I read the reviews about an electrical hand planer and the reviews were good. I got it and it worked great. I have purchase a lot of drill bits from Grainger.com but a bit more expensive. There is a Grainger store in town. I order on line and then just pick it up. Saves on shipping. Sometimes they have them on close out sale, where they essentially give the parts away! Also, if the metric size is close and is on sale I sometime buy it and use it for the imperial tap hole! Just convert to inches or vise versa. Anyway, drill bits wear out and you have to buy more, so you tend to stock the size that you use. You cannot resharpen the smaller ones by hand anyway. Also not worth it. Taps wear out too. Use oil. I commonly tap at 1/4-20 and 6-32 so I tend to stock up on these drill bits and taps. There are all kinds of taps! You will just have to read about them. Common sizes in Imperial that I use: 10-32, 10-24, 8-32, 8-24, 6-32, 4-40.

As long as you are going to get these things you will also want to get a thread pitch gage. These allow you to measure the spacing of the threads on a bolt to determine what it is. They are cheap and very handy. Something like: https://www.amazon.com/ChgImposs-Im...&sprefix=thead+gage,industrial,77&sr=1-3&th=1

Vice: I purchased my vice from PM when I got the mill. The one I ordered was out of stock so they just gave me the next size up, 6 inches. It is a nice vice, but it weights in at ~95#. It is precise. I am now older and it is all I can do to lift it to the mill table! I am pretty sure the one I got was this or its equivalent. VISE-HAV-6in-SB-SUPER https://www.precisionmatthews.com/s...tra-high-precision-milling-vise-wswivel-base/ PM has always treated me right and so I shop with them. Besides they are in Pittsburgh too ... and only about 20 miles from me.

I have an inexpensive scientific calculator that I keep in my tool box. However, I also have a scientific calculator on my Android phone. It is called "RealCalc" . It is quite powerful. There is a free version and a paid version. I have both as they enter data differently.i found out handling the phone with hands with way oil on them to not be very smart on my part.

- Joined

- Dec 18, 2022

- Messages

- 1,675

That is a good chart.... That will get you there...i found this link from little machine shop

- Joined

- Dec 18, 2022

- Messages

- 1,675

@tim81

This is the set I bought: https://www.harborfreight.com/power...peed-steel-drill-bit-set-115-piece-61543.html and as I said, as I replace individual bits I replace them with the more expensive Cobalt bit.

This is the set I bought: https://www.harborfreight.com/power...peed-steel-drill-bit-set-115-piece-61543.html and as I said, as I replace individual bits I replace them with the more expensive Cobalt bit.

- Joined

- Dec 18, 2022

- Messages

- 1,675

I have the "Machinist Calc Pro 2" app loaded on an old smart phone that I use. This app is designed for what we are doing and will calculate speed and feed based upon tooling ans materials among other things it does. The App cost me 20 bucks...I have an inexpensive scientific calculator that I keep in my tool box. However, I also have a scientific calculator on my Android phone. It is called "RealCalc" . It is quite powerful. There is a free version and a paid version. I have both as they enter data differently.

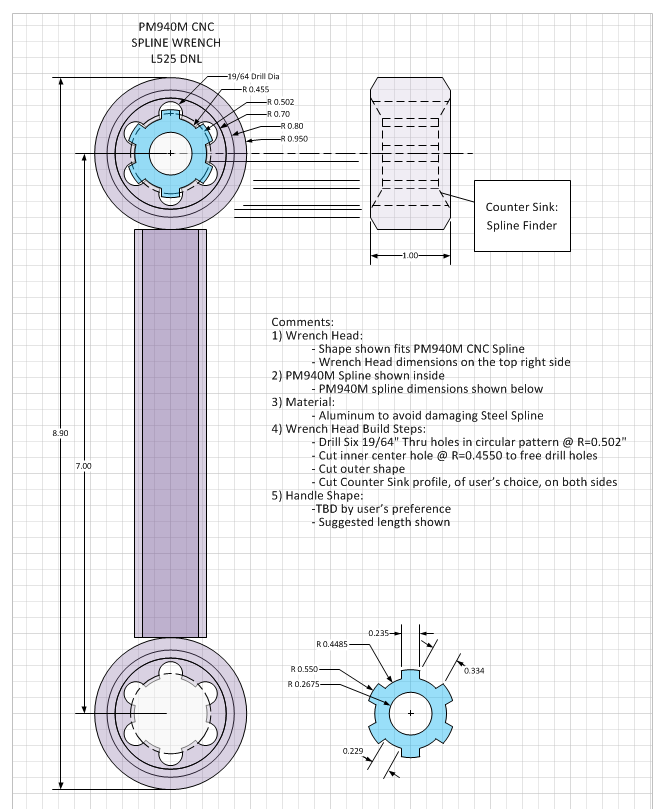

My 940M does not have a spindle brake, so it is difficult to get a collet out of the spindle with having a spline/quill wrench. There is a place to buy them, but not like mine. The mills should come with one, but mine did not. I like mine over what one can usually buy because it is thicker. Or you can make one. I will post the dimensions from a drawing I made. I was going to make one until I got the following.

By the way, earlier in this post there was conversation about a spline wrench. Since I live in Pittsburgh, I went to see PM. Matt had one at the time and helped me out. It may have been a sales sample someone gave him. I have no info on the manufacturer other than "Made in the USA". It is nice and big/thick. I will attach a couple of photos. It is made of Al and with the thickness it does not bung up the splines! I don't see it on the PM web site, but maybe Matt can get them, or can let us know where to purchase it. I looked around on the web, but never found anything quite like this one. I put a rule next to the wrench so you could get a perspective on its length and thickness.

Nice work, I don't have any ideas to add but I use the Luminar wrench for my spline. The other one is from a guy who makes them & sells them on ebay.

Luminar Products website

Luminar spline wrench - LMS

ebay spline wrench

I made my own drawbar wrench (very first part i cut) from this link. http://www.cnczone.com/forums/bench...-rf-45-industrial-hobbies-spanner-wrench.html

It works great and i used it for a month before buidling my own flip down style spindle lock. It sure elimina

I have the "Machinist Calc Pro 2" app loaded on an old smart phone that I use. This app is designed for what we are doing and will calculate speed and feed based upon tooling ans materials among other things it does. The App cost me 20 bucks...

Machinist Calc Pro 2

Nice one. Will safe it for later for sureYes I put the drill chuck a few times to see how the draw bar worked and it’s not the easiest way. It looks like you are reading my mindMy 940M does not have a spindle brake, so it is difficult to get a collet out of the spindle with having a spline/quill wrench. There is a place to buy them, but not like mine. The mills should come with one, but mine did not. I like mine over what one can usually buy because it is thicker. Or you can make one. I will post the dimensions from a drawing I made. I was going to make one until I got the following. View attachment 468891

View attachment 468889

So cool. Will get them too.@tim81

This is the set I bought: https://www.harborfreight.com/power...peed-steel-drill-bit-set-115-piece-61543.html and as I said, as I replace individual bits I replace them with the more expensive Cobalt bit.