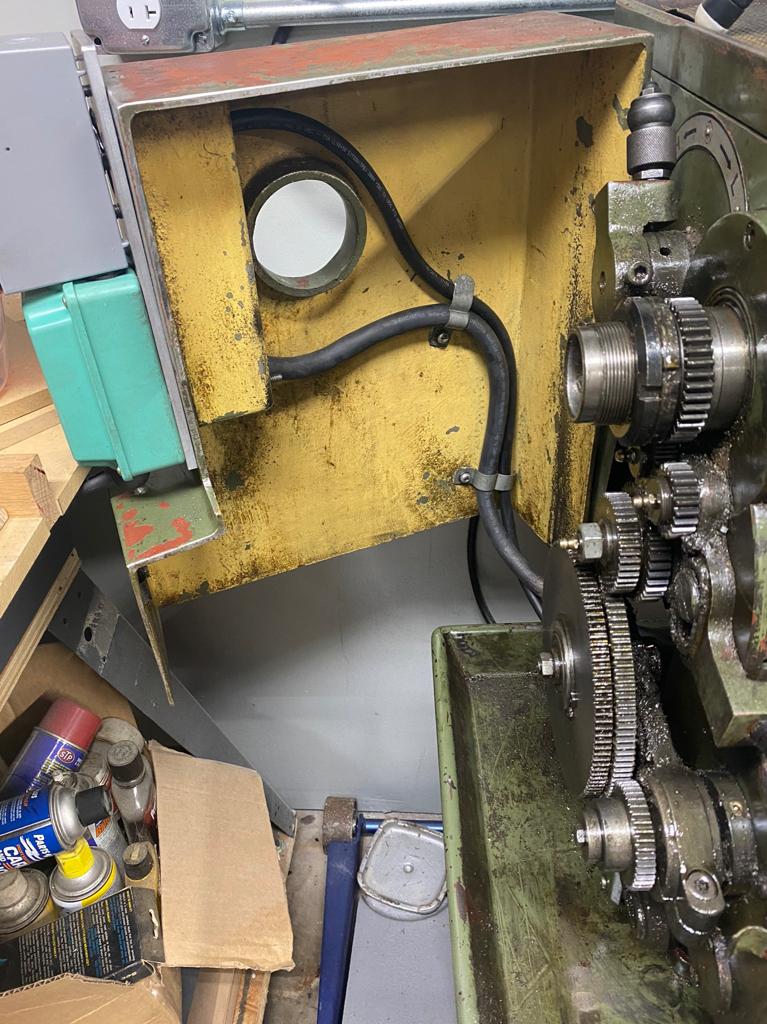

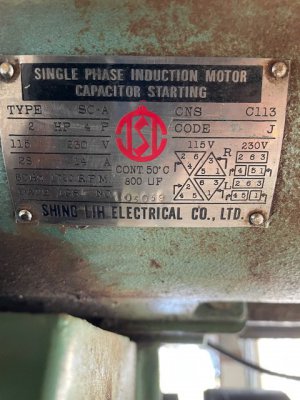

So last night I gathered enough courage to try and wire up my switch. IT WORKS!!!! Believe me I’m over here smiling ear to ear. Thank you all so much. I used the diagram in post #23. I runs backwards from what I’d like so I’m guessing I need to switch the run legs? The pictures are of the motor connections and the old switch. I probably will be installing a stop switch with a large stop paddle. Did jet ever put a foot brake on these type of machines? If so could someone post some pictures of the braking system. I might try to make something up for a foot brake. Again thank you very much to all of you