- Joined

- May 26, 2015

- Messages

- 764

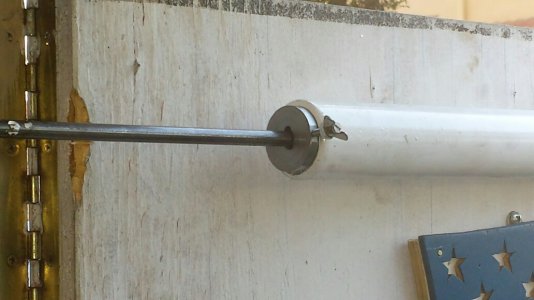

View attachment 122928 I'm waiting for Grizzly Tech Support to get back to me on the 9" faceplate. I could just go ahead and lathe the mount step larger and drill new holes but for the $144 I spent for this sucker I think I want the correct product.