-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking to get a 3D printer soon.

- Thread starter Flyinfool

- Start date

- Joined

- Feb 5, 2020

- Messages

- 117

The spitfire is now wall art, but I have a full set of parts for a second one when I get around to building it.

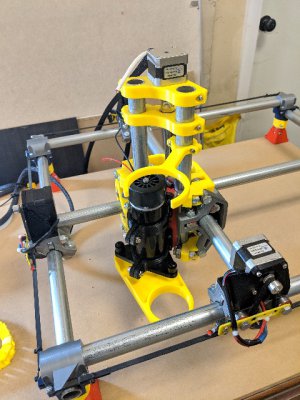

I had pretty good results in wood with the mpcnc but I wanted to use it for aluminum and that was just too hit it miss. That's what moved me to the atlas lathe and now the pm-30mv.......

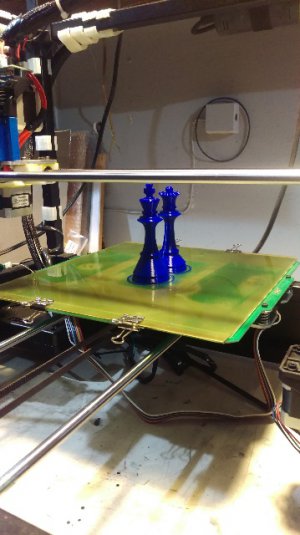

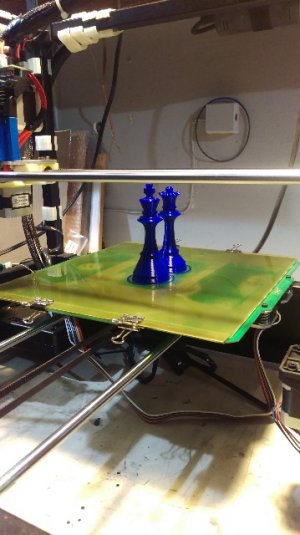

The yellow and blue chess set was made for a friend on the haribo/mk2.5s while the blue and white one was made about 4 or 5 yrs ago on my first 3d printer (rigidbot).

Lots of pics, but every post is better with pics.

I use onshape for 3d design. Not as robust as fusion but free and more importantly, simple and powerful enough for my needs.

I had pretty good results in wood with the mpcnc but I wanted to use it for aluminum and that was just too hit it miss. That's what moved me to the atlas lathe and now the pm-30mv.......

The yellow and blue chess set was made for a friend on the haribo/mk2.5s while the blue and white one was made about 4 or 5 yrs ago on my first 3d printer (rigidbot).

Lots of pics, but every post is better with pics.

I use onshape for 3d design. Not as robust as fusion but free and more importantly, simple and powerful enough for my needs.

Attachments

-

tmp-cam-7048543933506204653.jpg87.4 KB · Views: 161

tmp-cam-7048543933506204653.jpg87.4 KB · Views: 161 -

tmp-cam-5937515540063080142.jpg133.3 KB · Views: 150

tmp-cam-5937515540063080142.jpg133.3 KB · Views: 150 -

tmp-cam-8862539951998480122.jpg155.5 KB · Views: 153

tmp-cam-8862539951998480122.jpg155.5 KB · Views: 153 -

tmp-cam-3993118169399275726.jpg189.2 KB · Views: 153

tmp-cam-3993118169399275726.jpg189.2 KB · Views: 153 -

tmp-cam-4657029601305885141.jpg100.1 KB · Views: 152

tmp-cam-4657029601305885141.jpg100.1 KB · Views: 152 -

tmp-cam-3384557070501804655.jpg115.6 KB · Views: 152

tmp-cam-3384557070501804655.jpg115.6 KB · Views: 152 -

tmp-cam-444339171959528451.jpg115.6 KB · Views: 149

tmp-cam-444339171959528451.jpg115.6 KB · Views: 149 -

tmp-cam-8135390139472687546.jpg100.1 KB · Views: 147

tmp-cam-8135390139472687546.jpg100.1 KB · Views: 147 -

tmp-cam-2825483036268804526.jpg126.6 KB · Views: 152

tmp-cam-2825483036268804526.jpg126.6 KB · Views: 152 -

tmp-cam-8406103130590250260.jpg166 KB · Views: 146

tmp-cam-8406103130590250260.jpg166 KB · Views: 146 -

tmp-cam-2632131575125311988.jpg125.7 KB · Views: 154

tmp-cam-2632131575125311988.jpg125.7 KB · Views: 154

Last edited:

- Joined

- Jun 26, 2018

- Messages

- 1,733

Can you (anyone) get a finish straight off the printer that isn't so rough? That seems to be the way I see MOST come out. Now I do see may things Clough42 makes, and they look pretty smooth. I don't BELIEVE he is doing sanding and such, so I am curious if there is way/material/technique.

- Joined

- Feb 5, 2020

- Messages

- 117

Not sure what part you

The airplane skin turned out far smoother, but your always going to see the layer lines in fdm prints. There are some multi $1k fdm printers that can do 0.05mm but not worth it from my perspective as a hobbyist.

Not sure what your looking at, but if it's the blue chess pieces, that finish is because the rigidbot was a very very early printer and I believe I printed it with 0.3mm layer heights. You can reasonably go down to 0.15mm or possibly 0.1mm but it double or triples the layers required and therefore the time. For truly smooth layers you need sla or abs and acetone bath (not recommended).Can you (anyone) get a finish straight off the printer that isn't so rough? That seems to be the way I see MOST come out. Now I do see may things Clough42 makes, and they look pretty smooth. I don't BELIEVE he is doing sanding and such, so I am curious if there is way/material/technique.

The airplane skin turned out far smoother, but your always going to see the layer lines in fdm prints. There are some multi $1k fdm printers that can do 0.05mm but not worth it from my perspective as a hobbyist.

Last edited:

- Joined

- Feb 5, 2020

- Messages

- 117

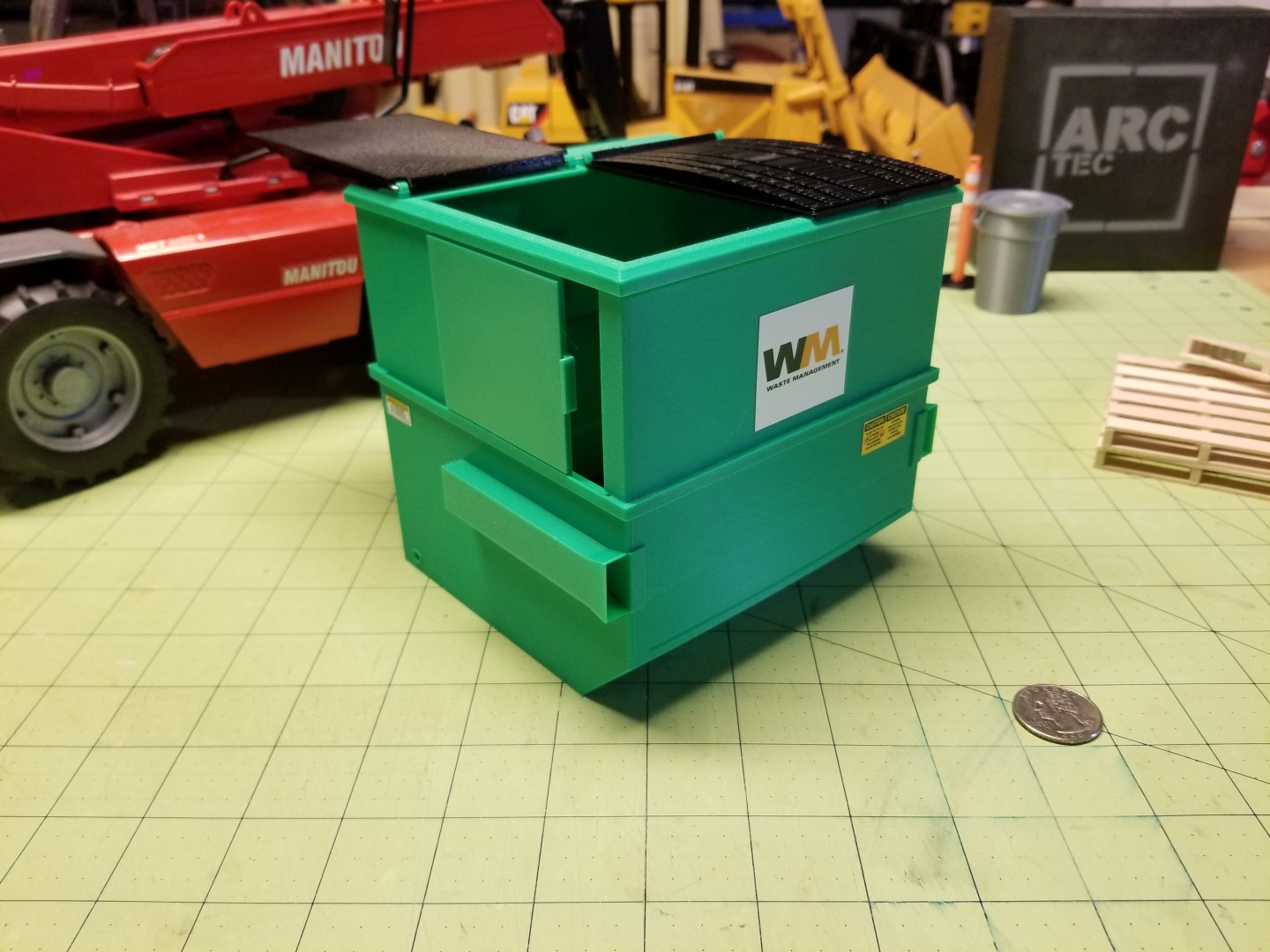

Yes, it's doable, but the chess pieces are 3" tall and I printed 32 of them even at 0.3mm layer height it took 3 or 4 days to finish. Each section of the spitfire was printed at 0.2mm layer height and the larger pieces take about 18hrs each. For parts the size your showing, I'd go sla and have no layer lines. It's a trade-off. If I printed the plane or the chess set at 0.1mm it would look very smooth but take a month...........I've made some relatively smooth parts... headlight assembly for a 1/14th scale Peterbilt truck. Tiny one is a radiator for a matchbox car.View attachment 329229 View attachment 329230

Based on the size of those parts, I'm guessing your using a smaller nozzle diameter? 0.2 maybe? Best part about these printers is they are quite versatile and each user can customize them to their needs.

- Joined

- Jan 7, 2016

- Messages

- 3,273

Were those printed on your Prusa? If so, what was your layer height and nozzle size?I've made some relatively smooth parts... headlight assembly for a 1/14th scale Peterbilt truck. Tiny one is a radiator for a matchbox car.View attachment 329229 View attachment 329230

- Joined

- Jun 25, 2020

- Messages

- 20

I do those parts with the SLA now and they're almost identical, aka no layer lines. Those were done with a 0.25 nozzle at 0.1 layer height. On the other end of the spectrum, some of the things I print take about 16 hours at 0.2 layer height.

- Joined

- Jan 7, 2016

- Messages

- 3,273

Ok, that is stinkin' cool. I googled some of the construction equipment that you were talking about. OMG. I have too many hobbies but those RC crawlers are damn cool. I showed it to my wife and she did not seem impressed, mostly because I like to spend money, LOL. Funny.... I have been into RC since I was 14 (40 years ago) but really had no idea your world was as extensive as it is. I do like my scale helis though. I flew professionally for 30 years so still have that aviation bug.