Brento, that is an interesting looking tool. The shape of the tool is up to the user but the rake and relief angles DO matter. Insofar as what material this tool was meant to work with, I have no clue. Tools for brass typically have zero to 5 degrees of positive side rake to reduce the tendency to dig in. Plastics work best with very positive rake tooling. This tool will generate very high cutting temperatures so it isn't for stainless or even mild to medium carbon steels. Cast iron responds best to higher side and back rake similar to stainless, not negative rake, in my experience. So, again, I have no idea what the maker of this tool was thinking or what material it would be optimized for.

Then there is the possibility that he did not understand lathe tool geometry.

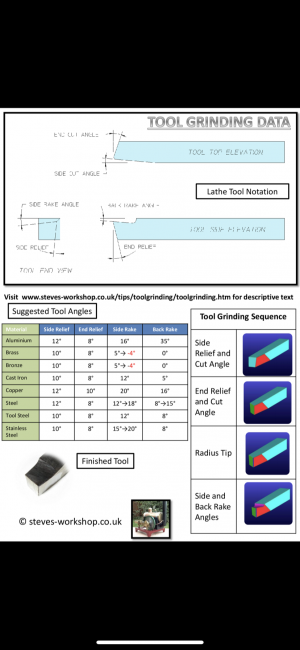

If you wish to turn brass, I highly recommend you use zero side and back rake. Grind a general purpose shape with about 12-15 degrees of side and end relief but leave the top flat. Put a 1/32" nose radius on it and I guarantee you this tool will not dig in and will leave a mirror finish.

For steels, I would definitely include positive side and back rake. For general use, a RH general purpose tool with 15 degree relief and rake angles works well (like our square tool). This tool will work with mild and medium carbon steels, aluminum, brass and plastics. It isn't perfect for any of them but it will work well with all of them.

You are going to find that the smaller the lathe, the more important tool geometry becomes. Take some time to read through the explanations of the various features on the tools in this thread so that you understand what does what. If you really want your tools to work well, you must grind them to do what you want them to do. I've put enough in this thread to give you all the answers you need. If that is not enough then sing out and we'll clarify it further.