- Joined

- Feb 2, 2014

- Messages

- 1,069

The withdrawal pains have gotten to be too much for me I just have to start another engine project. This one will be a flat head hit miss engine. Evidently flat head engines come in several different types and many different names. To me a flat head engine has the intake and exhaust valves in the engine block like a Briggs and Stratton or an early Ford V8 so that will be the type I will build.

1" piston

2" stroke

Ball type governor

Horizontal style

I make very few drawings, you can't even call them drawings more like layout scribbles. I am never sure just what the project will look like when it is finished as I make an assembly like a cylinder block and then everything else is fitted around that. The next component is built and the rest of the parts fit around that and so on.

I started with a piece of cast iron about 4" long and bored it for a 1" piston.

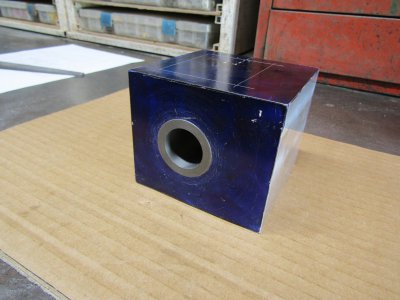

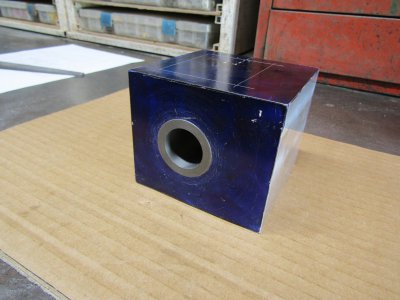

Next was a block of aluminum 4" X 3.5" X 3" that I bored to fit the liner.

And here they are for a test fit.

Note the rectangle marked in the top of the block.

Next to cut the water cooling area.

There was a lot of swarf from this.

And the finished water jacket with the liner slipped in.

The thicker side of the block is where the valve will go so that needs to be milled 3/4" deep.

I made the cavity extra deep and long to be sure to have plenty of room for for the valves.

This picture shows the valve box and the two holes in the front of the block are for the valve guides.

Note that the one hole has a matching hole in the opposite end of the block. This hole is for the exhaust valve lifter. The intake valve is atmospheric and is opened by vacuum.

I drilled and taped the holes for the cylinder head and gave it a good cleaning.

The liner was permanently installed with a liberal amount of lock tight.

The next step will be to deck the cylinder head end of the block to insure the liner and block are the same height but not until the the lock tight has set up.

Ray

1" piston

2" stroke

Ball type governor

Horizontal style

I make very few drawings, you can't even call them drawings more like layout scribbles. I am never sure just what the project will look like when it is finished as I make an assembly like a cylinder block and then everything else is fitted around that. The next component is built and the rest of the parts fit around that and so on.

I started with a piece of cast iron about 4" long and bored it for a 1" piston.

Next was a block of aluminum 4" X 3.5" X 3" that I bored to fit the liner.

And here they are for a test fit.

Note the rectangle marked in the top of the block.

Next to cut the water cooling area.

There was a lot of swarf from this.

And the finished water jacket with the liner slipped in.

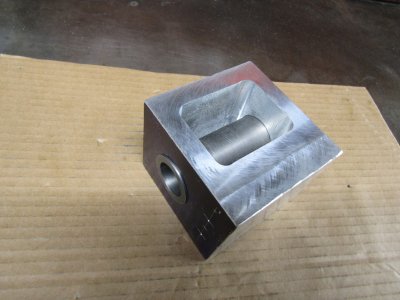

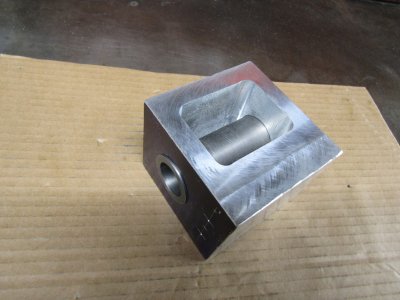

The thicker side of the block is where the valve will go so that needs to be milled 3/4" deep.

I made the cavity extra deep and long to be sure to have plenty of room for for the valves.

This picture shows the valve box and the two holes in the front of the block are for the valve guides.

Note that the one hole has a matching hole in the opposite end of the block. This hole is for the exhaust valve lifter. The intake valve is atmospheric and is opened by vacuum.

I drilled and taped the holes for the cylinder head and gave it a good cleaning.

The liner was permanently installed with a liberal amount of lock tight.

The next step will be to deck the cylinder head end of the block to insure the liner and block are the same height but not until the the lock tight has set up.

Ray