- Joined

- Jan 1, 2014

- Messages

- 233

Ray, could you elaborate on the setup using the boring head on the lathe in the first picture. Can't quite figure it out and my curiosity won't give up. Really nice work. Thanks.In the past I have always made the fly balls separately and drilled and taped them for the arms.

I thought I would try making them all in one piece on the lathe.

View attachment 440435

This worked out very well and a lot less work. I also made the spool and cross brace.

View attachment 440436

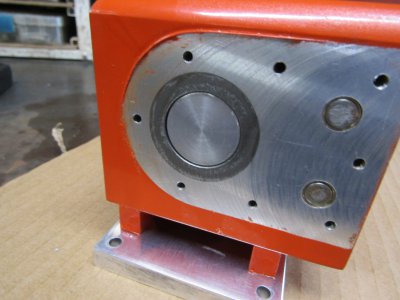

And a couple of pictures of the completed governor.

I still have to cut some off the shaft.

View attachment 440437

View attachment 440438

Next will be the hit miss mechanism.

Thanks for looking

Ray