I bet but my drawings are deceptive. The male thread doesn't pair with any female thread anywhere. It's a stud just stuck into a bare tube barely in contact with the two holes it's passing thru. So in my head the whole thing is increasing metal to metal surface contact and leaving just a few thou to encourage the silver to pool.its the ultimate seal/thread lock

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need info on a good oxy/acteylene set up for brazing

- Thread starter helmbelly

- Start date

I went to fire up the torch for the first time and found there are no flame arrestors. I ordered reg end but cancelled and am looking for torch end now. Not sure if I should get brand name - huge diff in price for a check valve. $69 for Harris, $15 for no name. They won't deliver until tomorrow - realistically am I in a hands off situation until they are installed - or can I fire it up in my driveway outside and practice adjusting diff kinds of flames?

Last edited:

- Joined

- May 7, 2023

- Messages

- 1,402

Sent you a PM about these. You'll be fine using the torch without to practice a bit, but long term their good to have.I went to fire up the torch for the first time and found there are no flame arrestors. I ordered reg end but cancelled and am looking for torch end now. Not sure if I should get brand name - huge diff in price for a check valve. $69 for Harris, $15 for no name. They won't deliver until tomorrow - realistically am I in a hands off situation until they are installed - or can I fire it up in my driveway outside and practice adjusting diff kinds of flames?

Just hook up and purge your torch, first with gas, then with oxygen., just crack the valve a bit and shut it off, each in turn.

You need to set your regs while the gas is flowing anyway, so this is a good time for that.

Purge would be with the torch connected to hoses and both torch valves opened so when you crack the tank handle you hear the gas squelch out the torch? Sorry to be so remedial - I have been around tanks but never paid attn to it.

- Joined

- May 7, 2023

- Messages

- 1,402

Oh absolutely have the torch connected, but no, what your describing is a very dangerous thing to do.Purge would be with the torch connected to hoses and both torch valves opened so when you crack the tank handle you hear the gas squelch out the torch? Sorry to be so remedial - I have been around tanks but never paid attn to it.

If you have both valves on the torch open and try to purge in this condition you can blow up the torch and lines. Any yourself.

You want to avoid mixing gasses in the torch handle at all costs.

No problem being careful with gas setups. I probably confused things for you with the purge step.

Last edited:

- Joined

- Dec 18, 2022

- Messages

- 1,746

I have a set of check valves in my system; but once in the torch that is where gas mixing occurs on the 00 tip it only has the 2 gas valves but on the cutting head it uses the 2 gas valves and a throttling valves so I am not understanding what we are talking about? Oxygen doesn't burn, it makes other things burn better like steel and magnesium for example. I will agree with you on one thing for certain, do not use pure oxygen to blow off a work bench because it will ignite and explode hydrocarbons (oils and greases...).Oh absolutely have the torch connected, but no, what your describing is a very dangerous thing to do.

If you have both valves on the torch open and try to purge in this condition you can blow up the torch and lines. Any yourself.

You want to avoid mixing gasses in the torch at all costs.

No problem being careful with gas setups. I probably confused things for you with the purge step.

- Joined

- May 7, 2023

- Messages

- 1,402

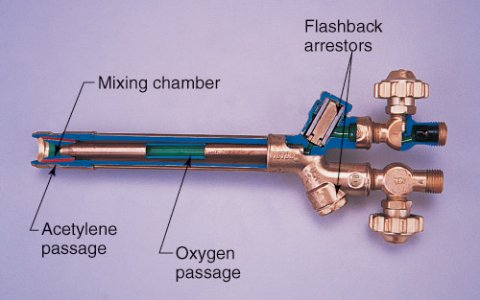

The gas only mixes in a certain part of the torch, mixing in other parts can happen in certain circumstances and if it does it can cause flash back.I have a set of check valves in my system; but once in the torch that is where gas mixing occurs on the 00 tip it only has the 2 gas valves but on the cutting head it uses the 2 gas valves and a throttling valves so I am not understanding what we are talking about? Oxygen doesn't burn, it makes other things burn better like steel and magnesium for example. I will agree with you on one thing for certain, do not use pure oxygen to blow off a work bench because it will ignite and explode hydrocarbons (oils and greases...).

It can also burn inside the torch given certain conditions. I have only seen it burn inside the torch once with it making a strange sound kind of like a whistling jet sound, and the guy dropped the torch and killed the fuel.

This is why you only crack the fuel bottle vs opening the ox fully.

I’m on my phone but I couldn’t find anything on the brazing torch handle, I’ll look later.

Basically the same thing happening but further up towards the hoses.

Edited the last post you quoted for clarity. Should have said “torch handle” or anywhere other than the mixing body.

Last edited:

- Joined

- Dec 18, 2022

- Messages

- 1,746

I know what you are talking about.... I have 3 torches, old Victor Contractor series and what you refer to as the handle is a flow divider on mine, it channels the Fuel up through several separate very small passages from the gas valve and the Oxygen through the center I believe that is correct, been a long time since I thought about it, and then they come together in the mixing chamber at the top of the handle.The gas only mixes in a certain part of the torch, mixing in other parts can happen in certain circumstances and if it does it can cause flash back.

It can also burn inside the torch given certain conditions. I have only seen it burn inside the torch once with it making a strange sound kind of like a whistling jet sound, and the guy dropped the torch and killed the fuel.

This is why you only crack the fuel bottle vs opening the ox fully.

I’m on my phone but I couldn’t find anything on the brazing torch handle, I’ll look later.

Basically the same thing happening but further up towards the hoses.

Edited the last post you quoted for clarity. Should have said “torch handle” or anywhere other than the mixing body.

This is the same as the handle I have which has the flash arrestors above the the gas valves, I take the cutting head off and attache the brazing tip in place of it. One of the three I have belonged to my father-in-law, one I picked up along the way and one I have had for almost 40 years.

Almost got to getting the new torch hot but after machining a few bolts and tubes to make into arms - I had read about the trick to a strong braze being all about a very clean metal surface. I'd also read the ideal surface to braze was a freshly machined surface. So I soaked all the parts in dish detergeant to get all the cutting oil off the stainless steel, then rinsed and the day was over. So I'll acetone in the morning and hope to post photos afterwards here.

- Joined

- Dec 3, 2020

- Messages

- 163

Stainless gets an oxide film that interferes with braze strength. To some extent the chemical action of the flux can dissolve the oxides, but you want to minimize the amount of work for your flux to do. So starting with freshly cleaned stainless will give better results.Almost got to getting the new torch hot but after machining a few bolts and tubes to make into arms - I had read about the trick to a strong braze being all about a very clean metal surface. I'd also read the ideal surface to braze was a freshly machined surface. So I soaked all the parts in dish detergeant to get all the cutting oil off the stainless steel, then rinsed and the day was over. So I'll acetone in the morning and hope to post photos afterwards here.

I'm not an expert, just a long-time (~50 years) practitioner. I don't know how fast the oxides form on SS at room temp. But I think letting them sit overnight might be getting into sub-optimal territory, so I would scuff up the SS right before brazing, with some abrasive cloth ("shop roll"), or scotchbrite. Abrasives can leave residue, so an acetone wipe after the abrasive scuffing is probably worth it. My fastidious prep for SS for brazing might be overkill, but I do get gorgeous braze joints on SS with perfect penetration and little to no burnt flux.

As to gases and tips: I used acetylene for 10+ years before switching to propane. I still have an acetylene bottle in the shop but it seldom gets used. Other than gas-welding, nothing I do needs acetylene, and I like propane just fine. For O2, I use an oxygen concentrator, the medical kind. Got mine used off Craig's for $150. With a concentrator, I don't have to refill O2 tanks ever again, and with propane in 20 lb bottles (gas-grill style), I never have to go to the welding-gas supply store anymore. Obviously 20 lb bottles wouldn't last long in a factory, but I am a retired hobbyist. Keeping several propane bottles around is cheap enough, and swapping in a new one when one runs dry is pretty quick..

I use the same torches for both O-A and O-P, but propane-specific tips keep the flame from detaching and blowing out, a common problem when using acetylene tips for propane. The tips I like best are made by Paige Tools in Seattle. They have a ring of small flames surrounding the main center flame, which makes the flame very stable and concentrated. It's not like a rosebud (tho Paige does make true rosebuds as well); the tips I'm talking about make a flame shape similar to a single-orifice O-A flame. Good pinpoint heat control.

A quick'n'dirty method for getting a propane flame to stay sttached with an acetylene tip is to counterbore the orifice. Hard to do precisely by hand, better if you have a lathe. Somewhere on the web they'll tell you the diameter and depth to counterbore them to, but I just did them by eye, bore about 4x the orifice size, and about that deep as well. Doesn't seem to be too sensitive to bore diam and depth. I call it counterboring, but I just used a regular twist drill, doesn't need a flat bottom. I think you can buy tips that have this done to them already, but if you're going to buy tips, just get the Paige tips, they're godlike.

Last edited: