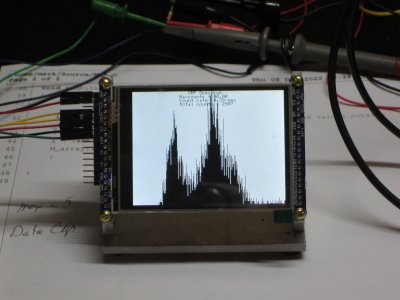

Update on trimming my aluminum "focus ring": there's still a substantial aluminum peak. Relatively speaking, the iron peak is higher so I know I've improved things _some_, but not enough to suit me.

Who made me make that ring out of aluminum, anyway? Oh, wait. It was me

The photo in message #1371 shows a spectrum acquired with the exact same settings, but with the focus ring intact.

I'm currently acquiring a no-sample background spectrum. The count rate is far lower so it's gonna take awhile.

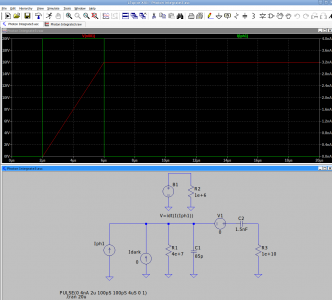

View attachment 435435

In general, you always have two clusters of energy. This happens regardless you take out the aluminium.

You are thinking this is because your ring is made out of aluminium, and you could be right!

You have been thinking it may help if it was made out of plastic.

Again, you could be right, but here, I think there might be surprises.

I think, at some stage, you should try to make it quit. Cut a small square of lead, and stick it over the photodiode. Do we get low or zero counts at all energies?

Take the shield away, and have it stare straight at a (bigger) sheet of lead. You might get peaks at 10.5KeV and 12.6KeV, or only one peak if resolution is low, perhaps from not enough bits.

There might also be seen, a whole lot of peaks. This might be from aluminium, or plastic, or depleted photons re-emerging.

Might the group to the right be a pile of leftover photons having expended initial energy making the group to the left? This is just mad speculation!

I would be quite interested in seeing what happens when it is shown a direct view of a Am241 source put right up against the photodiode. One would want something to happen way to the right, where 60KeV would be.

The count rate seems really slow. We have to wait a long time to get results.

I have been thinking about this. It involves figuring out where all the available decays went to.

I do get it that we can only use a limited solid angle from the source for practical reasons, but we make it as wide as possible consistent with only energizing the sample region. Your scheme that does not bury the sources way down in a lead pot, is, I think, the right approach, and I have modified the design of the lump I intend to put together to have it this way. (Still at the tin can + burner stage)!

I am actually considering a 16 smoke detector sources thingy.

(The first try will be with 8)

This has to start to make sense, or I be thinking we got short-changed by Ali Express with feeble smoke detectors!

You are right in that our designs are converging into very similar schemes. The saying is "wheels are round"!

I do expect that when I power up, I will initially be looking at an incomprehensible racket, and I will have to work back from the ADC, making it become predictable. I will get there!