- Joined

- May 27, 2016

- Messages

- 3,479

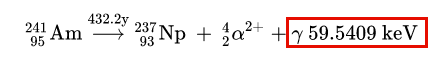

It's way worse than that! There is a mad shower of secondary photons scattering everywhere when one of these decays into Neptunium.Good thoughts on checking the detector. Back to first principles, block the radiation with lead, what is the background. Then 1 source only. Think I'll make a square aperture in lead, shielding the detector board as well.

A thought - won't we also be seeing the source carrier? That speck of Americium is sitting on some material, what is it? Won't we always see it's signature? It's getting bombarded. I'd expect that material spectrum would be present with source only.

Of course I'd be happy to see any pulses at all! Still a ways from that.

Fortunately, the main type of decay is in near 100% of the stuff.

A secondary type of spontaneous fission has a minuscule fraction, only 3.6 trillionths at 1.2 per second per gram. We can ignore it!

The rarest kind is decay into Tellurium(81), and on into Silicon(14). At 7.4e-16, I am surprised anybody ever discovered it! Ignore it.

As you know, I am getting hardball in trying to figure how much we can expect to count. This is about more than the obvious things, like the solid angle we can manage aimed at the test stuff, compared to the sphere area around the source. We have to get as close as possible, and shield as little as possible consistent with denying a path to the detector.

There is another solid angle we have to consider, because the fluorescence is not obliging enough to head straight up a cone heading toward the PIN photodiode. Also, there may be more re-emitted photons (I think) of part expended incoming.

Maybe here, you don't want to go down the murky route with me into nuclear physics!

We have ..

I am not sure if all of this happens simultaneously.

Apparently α-decay energies 5.486 megaelectronvolts (0.8790 picojoules) for 85% of the time

Another 5.433 MeV (0.8705 pJ) for 13% of the time

5.388 MeV (0.8633 pJ) for the remaining 2%

The energies on all the decays is near the same. I am sure some physicist can account for all the other minor little bits that happen. When a decay happens, it can be any one of those, mostly alpha. When a gamma happens, it is much higher energy, just not as often.

2% of the decays have a γ-ray energy 59.5409 keV (9.53950 fJ) happening. I take it that then only 2% of the 33300 decays can be expected to be gamma, which is why I applied the percentage later.

About the source, and the other stuff in it and around it.

It starts with AmO2, the oxide, mixed thoroughly with gold, fused 800C into a little briquette.

Then a backing of plated silver, and a front covering of gold or palladium, hot forged on.

Then, like all gold leaf, (this one with Am241 oxide contaminants), it can be rolled out very thin, into 0.2mm, or maybe 0.008" foil.

The top cover of gold, there to stop corrosion I guess, is about 2 microns thick

It comes as a 20mm wide strip, and the sources are punched out of the strip. I have to take a look to see the actual size of the punching.

This is then mounted into the little circular metal carrier, about 1/4" diameter, which itself is held in on a approx 10mm metal disc with a terminal tag, which we take off. My sources are not handy right now, but have a try with a magnet. Am241 is a metal, but there is so little there (fractional micrograms), you won't discover from a magnet, if it was ever magnetic in the first place. If the surround is plated steel, you get to find out.

How many per second?

I don't know yet

0.9uCi decays means 0.9e-6 x 3.7e+10 decays per second. That is about 33,300 decays per second.

We lose the ones heading in the wrong directions, getting only the ellipse that lands. It is some fraction of the sphere about 20mm radius.

Loosely, that's about 1250mm2 out of 4*π*20*20 sphere = 5026 mm2. or near 24% , maybe 25%.

Then again from everywhere that got hit, multiply again by a fraction heading towards the detector, but this time starting from a wider region, rather than a point-like source. Loosely, we end up with around 2000/second.

But we have 8 sources, so let's make that 16000 per second.

Then we have the probability curve. If aluminium, think about 1% or 2%

If iron, then pretty much 100% probability of detecting it, if its result came our way, toward the diode.

I left one out. That is the probability of incoming photon hitting an atom in the test material cross section and yielding a fluorescence. That is not 100%, but the x-rays can travel out of the material so long as it's not lead.

Again, loosely, and conservatively, reduce the 16000 to (say) 5% . That is still 800Hz !

OK then, make it 1%, that is still 160 Hz. That more than accounts for the 2% yield from the source.

We would accumulate a 10,000 count in about a minute!

Even if it were only 20 detections per second, we could get a 10,000 count in about 8 minutes.

What do I think?

I think I don't know what I am doing!

Either a whole lot of counts went missing because of construction inefficiencies, or lack of our ability to discover them electronically, or there is something about my expectation of how much should be happening is totally wrong!

Last edited: