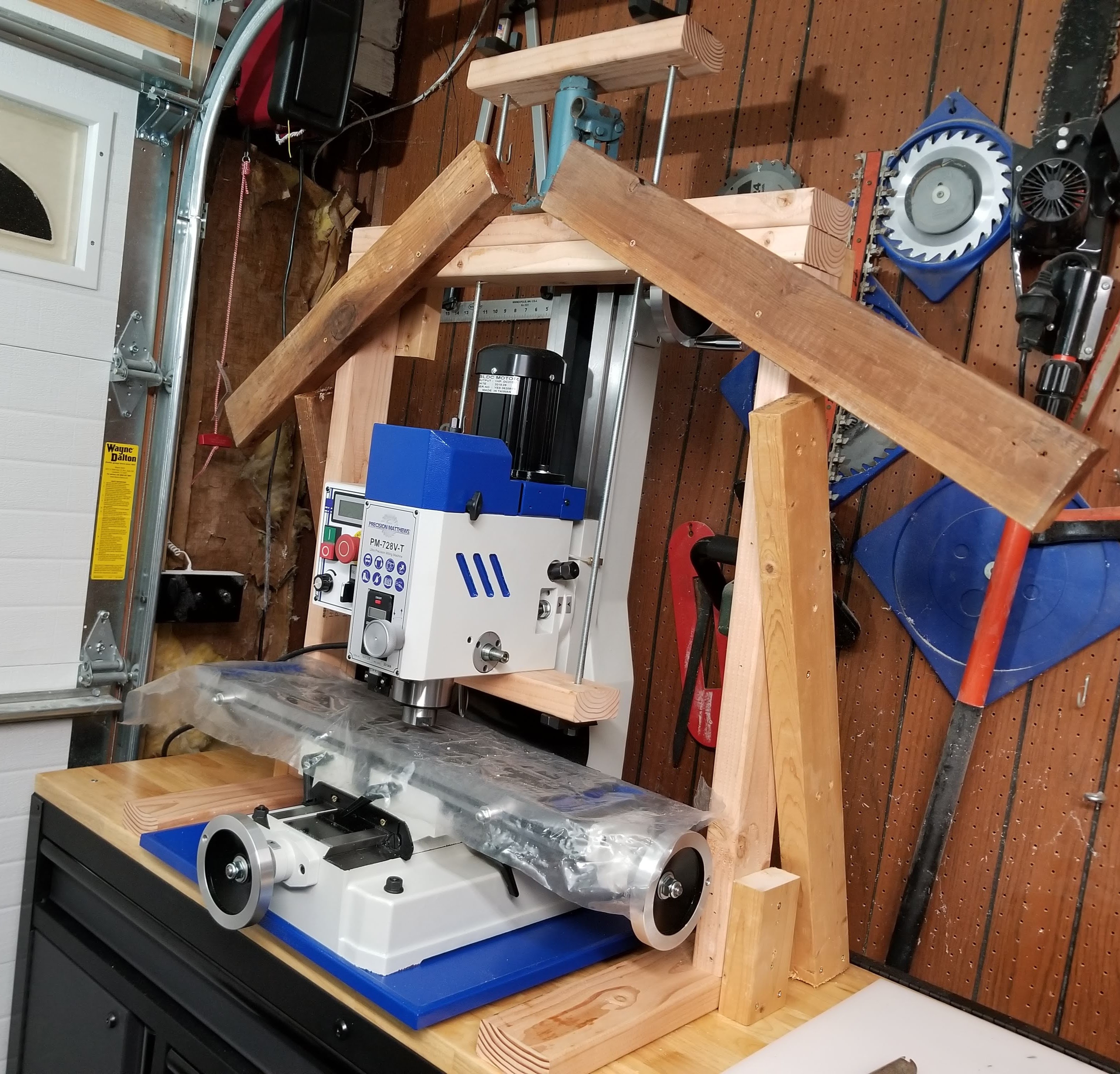

Still need to get the drip pan underneath, but the machine is about where it belongs. Have to figure out a clever way to temporarily lift it to get the pan under, another friend's shop hoist doesn't fit under the workbench. There's only about 6.5 inches underneath. Some hoists have lower wheels, but I may rig something simple with a hydraulic jack.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New model of a small mill coming, some manufacturing pics from the factory to look at.

- Thread starter qualitymachinetools

- Start date

- Joined

- Sep 8, 2019

- Messages

- 4,392

I was the friend that helped Alan B. today. As far as I could tell, the mill was flawless in appearance. I have a PM-25MV, and the PM-728VT is clearly a step above my mill. I have zero complaints about my PM-25MV, so you can see how impressed I am with this Taiwanese machine.

I was very happy that Alan appears to have received an undamaged machine.

I was very happy that Alan appears to have received an undamaged machine.

Attachments

- Joined

- Dec 13, 2019

- Messages

- 3

So I'm fairly new to the machining world and I'm in gunsmithing school in Arizona. I have read others posts who would say such a beautiful mill, albeit very well made, is simply to light to keep tolerances and work steel. I will not be doing any barrel fluting and I don't need the long bed of a full size mill, so I wonder if a machine this size and weight would be suitable for such work?

I'm not in a position to address ArCustomRifle's question, hopefully someone with more experience can answer. This machine is much stiffer than my previous mini-mill, and my understanding is that it will cut steel just fine, but most of my needs are in softer materials and this machine is more than capable of that. Due to the small size it is pretty stiff, and this particular model has about 100 pounds of heft over the usual small mills (370 pounds vs 275 for a pm25).

Today I cobbled together a wood gantry and used a hydraulic jack to lift the mill 40mm and get the pan underneath. The gantry is screwed together with 2 1/2" drywall screws, the load is carried in wood compression and tension is only in the 3/8" all thread. Parts from the clamping kit were used to spread the forces over the wood at the ends of the all thread. The less than two minute lift was totally uneventful after several hours of cutting and screwing. The hardest part was keeping good right angles during assembly while putting the screws in without pilot holes. The temporary gantry is already partially disassembled, it goes back into the scrap lumber pile.

Today I cobbled together a wood gantry and used a hydraulic jack to lift the mill 40mm and get the pan underneath. The gantry is screwed together with 2 1/2" drywall screws, the load is carried in wood compression and tension is only in the 3/8" all thread. Parts from the clamping kit were used to spread the forces over the wood at the ends of the all thread. The less than two minute lift was totally uneventful after several hours of cutting and screwing. The hardest part was keeping good right angles during assembly while putting the screws in without pilot holes. The temporary gantry is already partially disassembled, it goes back into the scrap lumber pile.

- Joined

- Sep 8, 2019

- Messages

- 4,392

Nice work on the gantry.

You can tell that Alan is an engineer what with thinking about compression and tension.

It looks like he will be making chips in a matter of days!

You can tell that Alan is an engineer what with thinking about compression and tension.

It looks like he will be making chips in a matter of days!

- Joined

- Mar 21, 2013

- Messages

- 4,063

So I'm fairly new to the machining world and I'm in gunsmithing school in Arizona. I have read others posts who would say such a beautiful mill, albeit very well made, is simply to light to keep tolerances and work steel. I will not be doing any barrel fluting and I don't need the long bed of a full size mill, so I wonder if a machine this size and weight would be suitable for such work?

Not sure how to answer this. I've 'kept tolerances' while building competition 1911s and 2011s on smaller machines than this. I've also seen people screw up on much larger machines. I think it's more about the operator than the machine, but that's just me.

A quality machine will allow a operator to work within his skill limit more easily. A low(er) quality machine makes this much more difficult.

I built my first open class 1911 on a Sherline lathe and mill. This after being told by a 'real machinist' that those toys couldn't do it. But TBH I wouldn't want to have to do it again.

This machine is much more stout that my PM25, and I milled iron, 4140, stainless, aluminum, and titanium on it. The mill above would have just made the job easier. A lot easier.

A friend of mine is building full-on custom 1911s with all the flat-topping, french borders, and ball cuts on a PM25 sized machine (Griz version) and does an outstanding job. And his order books are full. I also know that he'd love to have a bigger machine to make setups easier, but it's going to be a while before he can do that so he works with what he has.

- Joined

- Mar 21, 2013

- Messages

- 4,063

To be honest though, if I was in the market for another small bed mill for pistolsmithing, I'd be looking at the 833T. It's a little bigger, has a slightly larger work envelope and still has the Taiwan quality and accuracy.

But if I could only afford a machine this size, I'd jump all over the 727. But I mostly do pistol work (disclaimer).

But all this is just one person's opinion of course.

But if I could only afford a machine this size, I'd jump all over the 727. But I mostly do pistol work (disclaimer).

But all this is just one person's opinion of course.