-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New PM 932M-PDF arrival

- Thread starter yota

- Start date

- Joined

- Nov 23, 2020

- Messages

- 787

Grain of salt. I have never trimmed a mill before, but a half thou over 6” SEEMS pretty good to me on nod. Especially considering what you would need to do to correct it.just watched David Best's video that he posted on the 940 thread so it looks like I have a few other things to check also.

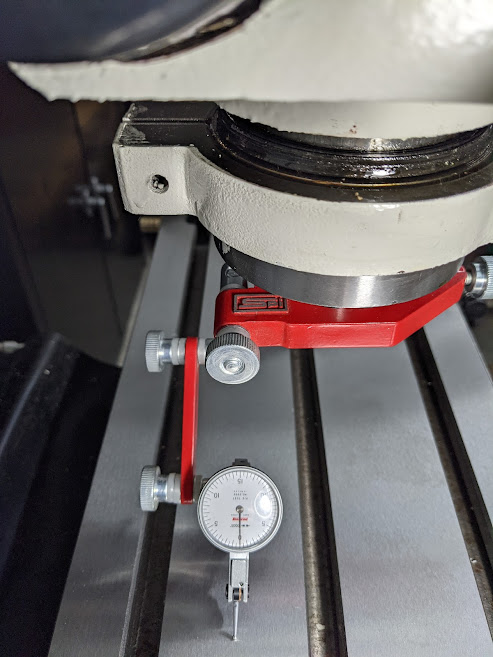

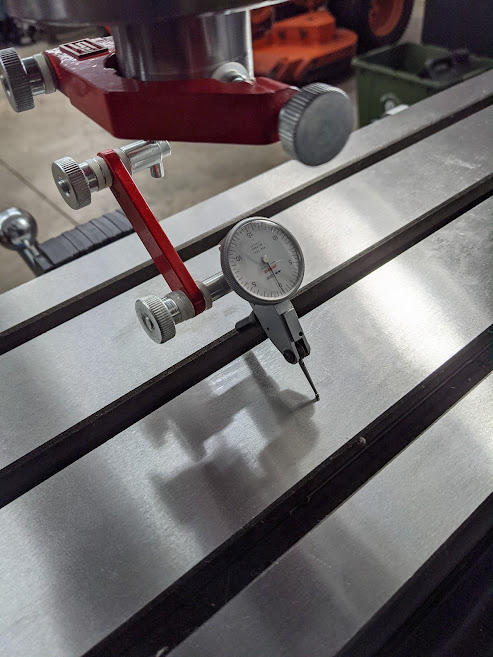

so I set up to install and indicate in my vise. while I had the test indicator on the spindle I thought I would check the table again. not sure if this is a good method for checking or not but I ran the indicator on the table for the full width in the X axis under power at low speed. the needle didn't move more than a half thou in the full length of travel from stop to stop and most of the way it was way less than that. I was amazed. I then hand cranked it in the Y axis across the full width of the table and it confirmed the half thou that showed with the double dial indicator method. what was interesting was that it stayed very close to zero from the back edge until it reached the front 2 inches or so. the double dial tool shows the variation but not where it occurs. I was going to try the method in David Best's vid but I hate to admit that I don't yet have a precision square.

Last edited:

video on post number 10.

www.hobby-machinist.com

www.hobby-machinist.com

Pm 940v

***Edit below*** ive since addressed the issues discussed in this thread. Hopefully things hold up because im really liking this mill. Alright i need help again hah. Im going through testing mill alignment. Mill table movement is flat in the x and the Y. I know you're not really supposed to...

www.hobby-machinist.com

www.hobby-machinist.com