-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New PM25MV on the way!

- Thread starter JohnsonFabrication

- Start date

- Joined

- May 10, 2014

- Messages

- 74

yeah, I was pricing out what a chunk of steel that size would cost, seems to be around 300 bucks for one big enough to make the saddle out of, so let's see, 80 dollars for the saddle, vs 300, yeah, i'll go with the 80 dollar one. With what I've got from the other parts, I'm probably going to have to do some scraping anyway, I'm pretty sure it's in rough condition like the other new parts.

- Joined

- May 10, 2014

- Messages

- 74

Update: Been working a lot of hours, not as much time as i would like to work on the machine, but i do have some new information, and should have some new pictures to post later this coming week.

1st. Been looking at motor options, vs the stock motor. The PM25MV i am probably going to leave alone for now, and change the motor on the cnc machine head. What I have been looking at: At first, i thought i would go with the Sangmutan motor that Keling/Automation Technologies sells. Then i saw the multiple threads of problems with the controllers of those motors. The threads say they have been updated but there still seems to be a few nagging problems with them here and there. Then I looked at a three phase motor, this has more promise, but the 56C of a nema motor is quite large for the mill head. I started looking at 3 phase metric motors, it appears that the Sangmutan motor has the bolt pattern of an IEC D80C metric motor. this is good news. A D80C motor is a bit smaller than a 56C for the same horsepower. I ordered a 1.1kw (1.5hp) Leeson motor, model number 192067.30, this motor spins at 3600 rpm, and with a vfd should give a very nice rpm range for the mill. at the face mount flange, the Leeson motor is only 1 inch diameter bigger on the outer edge of the flange than the Sangmutan motor. The motor mount plate i already have is made for the sangmutan.

2nd. The bad news. The D80C motor has a shaft of 19mm diameter with a 5mm key. The sangmutan motor has a 14mm shaft with a 4mm key. I am going to have to bore out the motor pulley and broach a larger keyway. Also, the increased motor diameter may overhang the motor mount bolt slots, so i may have to countersink them for flathead screws to clear the motor flange, i hope not, but we will see.

3rd. Picking a vfd. I am familiar with vfd's, i had one on a bridgeport i used to have (it was a teco unit). I am thinking about getting a Leeson nema 4x enclosed drive and mounting it directly to the mill head, where the electrical box originally was. the problem is the nema 4x units are quite a bit more expensive than the open frame ones. The trade off is that the open one should be in a pretty large enclosure, which i do not want to mount on the mill head (10 x 12 x 8 box). Another option is the Hitachi WSJ200 drive. While this is not nema 4x, there are wiring diagrams available so i can hook it up to my C32 breakout board with no problems. Not so with the nema 4x drives. Tough choices, and all somewhat expensive. I am still undecided at this point.

1st. Been looking at motor options, vs the stock motor. The PM25MV i am probably going to leave alone for now, and change the motor on the cnc machine head. What I have been looking at: At first, i thought i would go with the Sangmutan motor that Keling/Automation Technologies sells. Then i saw the multiple threads of problems with the controllers of those motors. The threads say they have been updated but there still seems to be a few nagging problems with them here and there. Then I looked at a three phase motor, this has more promise, but the 56C of a nema motor is quite large for the mill head. I started looking at 3 phase metric motors, it appears that the Sangmutan motor has the bolt pattern of an IEC D80C metric motor. this is good news. A D80C motor is a bit smaller than a 56C for the same horsepower. I ordered a 1.1kw (1.5hp) Leeson motor, model number 192067.30, this motor spins at 3600 rpm, and with a vfd should give a very nice rpm range for the mill. at the face mount flange, the Leeson motor is only 1 inch diameter bigger on the outer edge of the flange than the Sangmutan motor. The motor mount plate i already have is made for the sangmutan.

2nd. The bad news. The D80C motor has a shaft of 19mm diameter with a 5mm key. The sangmutan motor has a 14mm shaft with a 4mm key. I am going to have to bore out the motor pulley and broach a larger keyway. Also, the increased motor diameter may overhang the motor mount bolt slots, so i may have to countersink them for flathead screws to clear the motor flange, i hope not, but we will see.

3rd. Picking a vfd. I am familiar with vfd's, i had one on a bridgeport i used to have (it was a teco unit). I am thinking about getting a Leeson nema 4x enclosed drive and mounting it directly to the mill head, where the electrical box originally was. the problem is the nema 4x units are quite a bit more expensive than the open frame ones. The trade off is that the open one should be in a pretty large enclosure, which i do not want to mount on the mill head (10 x 12 x 8 box). Another option is the Hitachi WSJ200 drive. While this is not nema 4x, there are wiring diagrams available so i can hook it up to my C32 breakout board with no problems. Not so with the nema 4x drives. Tough choices, and all somewhat expensive. I am still undecided at this point.

- Joined

- May 10, 2014

- Messages

- 74

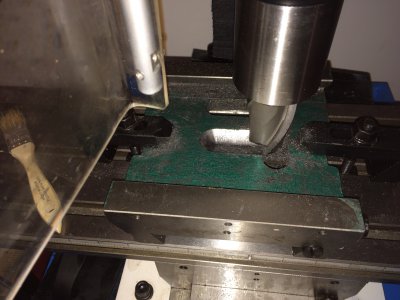

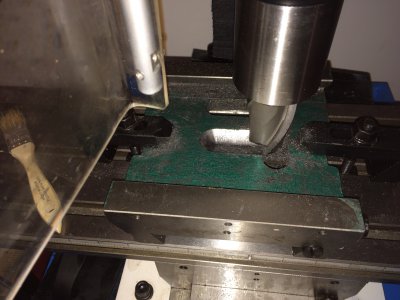

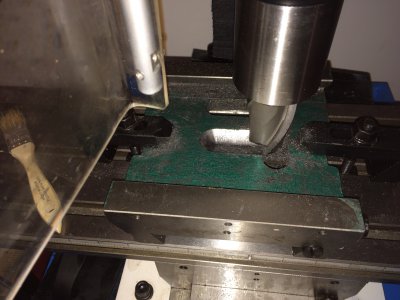

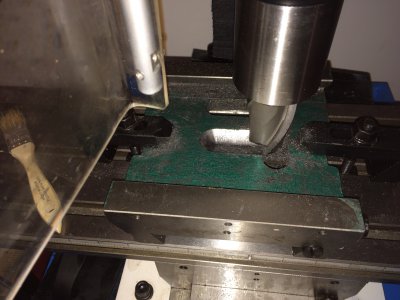

today i clearanced the saddle for the ball screw nut. I used a 2-flute 1-1/2in ball end mill with a 1-1/4in end mill holder. almost too big for the PM25, had to take lots of small cuts.

I then test fit the saddle, base, table, and ball screws together. I am going to have to widen the slot in the table slightly, but I am happy, today i made some real progress.

I then test fit the saddle, base, table, and ball screws together. I am going to have to widen the slot in the table slightly, but I am happy, today i made some real progress.

- Joined

- May 10, 2014

- Messages

- 74

Got the 3d printer fired up today. printed out a motor cover for my 60mm stepper motor. Used the model that is available on http://www.g0704.com. I was going to post some photos and the 3d model files for the custom electrical enclosure i designed for the WJ200-015SF vfd, but it looks like i can't attach files directly anymore, boooo!. I don't want to sign up on a hosting site so i guess there will be no more photos unless i'm doing something wrong, but i will keep you guys posted on progress.

The motor I am going to use is a Leeson 192067.30 1.1kw 3600 rpm D80C frame 3-phase motor. This is a 1-1/2 hp motor, and has the same bolt pattern as the Sangmutan BLDC motor. This motor is going to add 34lbs to the head.

The motor I am going to use is a Leeson 192067.30 1.1kw 3600 rpm D80C frame 3-phase motor. This is a 1-1/2 hp motor, and has the same bolt pattern as the Sangmutan BLDC motor. This motor is going to add 34lbs to the head.

- Joined

- May 10, 2014

- Messages

- 74