- Joined

- May 26, 2015

- Messages

- 875

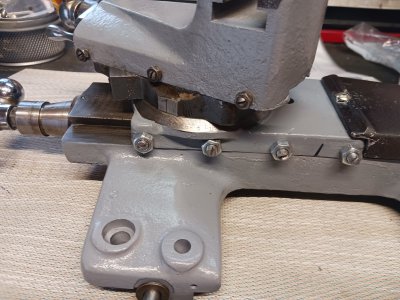

Can someone tell me if my bearing dust cover and oil seal is installed properly? Yes the oil holes are aligned on the dustcover cups. "Seems" like the spindle gear end oil seal, (spacer 10A-6), sticks out too far and won't go in any further and on the nose end the dust cover stick too far out! Could anyone post me a pick of their seals? The way they currently are don't believe they will impede anything. ( Hope, if wrong, I don't have to tear the head all the way down just for the oil seals and dust covers.) Thanks

Update 4/16 @ 1:40pm. Just watched a Tubalcain video and it "appears" that I have done it correctly.

Update 4/16 @ 1:40pm. Just watched a Tubalcain video and it "appears" that I have done it correctly.

Attachments

Last edited: