- Joined

- Jul 29, 2015

- Messages

- 91

Nice and tidy. Good job!

Thank you!Slodat, That looks fantastic. Great Job.

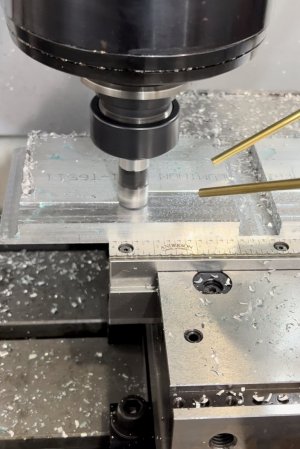

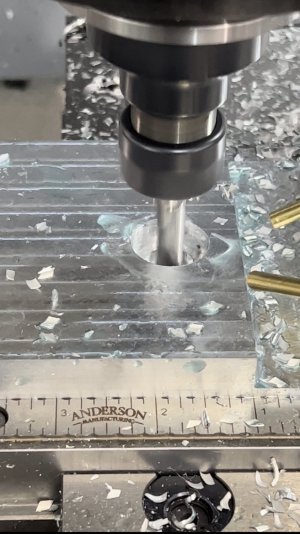

I owe you a beer for catching the tool changer issue prior to me crashing the machine. Thank you!!Nice and tidy. Good job!

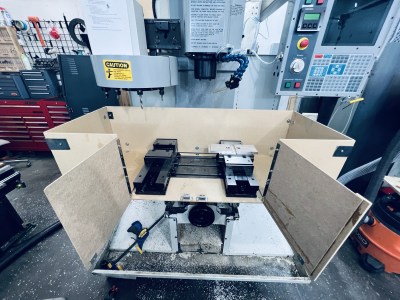

Like I said in my most recent post, I think the old Haas is going to be a great machine. The Calmotion unit is a must have in my opinion. I'm happy with it for what it is. I want a newer machine for the probing mostly.Wow. Have been looking at old Haas units.... Didn't realize it would be this hard to get to work. Thanks for updating us, and please keep doing the updates!

I honestly don't know. I suspect it may have some sort of conversational. It's not of interest to me. I find conversational programming to be onerous compared to CAD/CAM.Excellent! Glad you got it working. With the older style Haas control( the ones with the analog spindle load meter ), is there a conversational function, or is it strictly use it like a manual mill and/or full cnc?