-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Next project: Craftsman 101.07301 6" lathe

- Thread starter LX Kid

- Start date

- Joined

- Dec 25, 2011

- Messages

- 10,511

Try zooming in until the pixels are about 1/4" square. You will see that the black is no longer all black. And that there is about a 5 pixel wide band around each nominally black line where the scanner couldn't make up its mind as to whether the pixels should be black, white or something in between. And then it finally settles on the correct color being yellow. The yellow has zero information content and only serves to inflate the file size. Had it been scanned properly in monochrome with the grass cutter properly set, the indeterminate band would only be one pixel wide. I've been doing this commercially with high-end equipment for more than a quarter-century and know what it takes to make new looking scans of 30 to 100+ year old originals.

In any case, the file in question is already available in Downloads. But the best and most nearly correct one for the 618 and the slightly later 101.21400 is the cleaned up scan of the one that came out in 1950. It is the basis for the one that I'm working on for the 101.07301.

In any case, the file in question is already available in Downloads. But the best and most nearly correct one for the 618 and the slightly later 101.21400 is the cleaned up scan of the one that came out in 1950. It is the basis for the one that I'm working on for the 101.07301.

- Joined

- May 26, 2015

- Messages

- 764

Still moving in "slooooow moooootion." No excuse for not doing something to finish it off. Just have to bolt the lathe, motor and countershaft assembly down to the base board. Had a 120 year historic 91 degree day yesterday and the virus scare just puts a damper on all my actions. Maybe it's like Scarlet O'Harra said at the end of Gone With the Wind, "Tomorrow will be a better day." Not going to use the DC motors and will save them for some other project.

Last edited:

- Joined

- May 26, 2015

- Messages

- 764

Well time really flies by! It's only been 1-1/2 years and I started back on this project yesterday. I had already stripped all parts, cleaned, primed and painted by April of "last" year. All I had to do was mount it and do all the necessary adjustments and lubricating everything. Never did find/buy a motor mount so I just solid mounted it to the bench. Found some pulleys, not correct size, but they they work fine for now. Low speed is 560 rpm and high speed is 1680 rpm. Don't have a tool post but ordered a OXA QCTP from Amazoo and should be here in a couple of days. Az lucky lucky for me I already has a full set of change gears from another Craftsman lathe I used to own about 20 years ago, not that I would probably ever use them. I turned it on for the first time today and it hums like a Singer Sewing Machine.

Attachments

Last edited:

- Joined

- Dec 25, 2011

- Messages

- 10,511

Looks much better. I see that you found a tailstock lock lever.

If you have the other set of jaws for the 3-jaw chuck, I would strongly recommend installing them. They will make access to the part mounted in the chuck much better.

If you have the other set of jaws for the 3-jaw chuck, I would strongly recommend installing them. They will make access to the part mounted in the chuck much better.

- Joined

- May 26, 2015

- Messages

- 764

I also am left handed and so I guess it will stay where it is.OK. My Father would probably have liked the back gear lever on the left. He was left-handed, AFAIK the only one in five generations of my family to be so.

- Joined

- May 26, 2015

- Messages

- 764

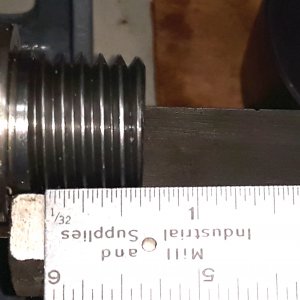

I'm gonna have to come up with another chuck instead of the one I now have. My chuck is an outside grab and I want an inside holding chuck. If only I had the extra jaws would have been great. I don't have a thread gage that will tell me if the spindle TPI is 8 or 10. I "think" being it has bronze bushings that it is an 8 tpi. If were Timken roller bearings on the spindle I "think" it would be a 10 tpi. Anyone want to do any chuck trading or selling the one you have????

Attachments

- Joined

- Apr 5, 2013

- Messages

- 391

Hi Kid , thanks for documenting the restore I think you did a fine job . You are correct the 6" has a 1"- 8 tpi spindle thread and sorry I don't have a spare chuck . Because the 6" has a # 2 Morse taper in the spindle it is inexpensive to make a collet set up and get a chuck with a M2 shank . https://www.ebay.com/itm/164533454179?hash=item264ef54563:g:e-cAAOSwq-dfvJ91 One thing and it will be a quick fix , the lathe's risers (feet) you have reversed . The Atlas / Craftsman 6" had a 3 point mount , where as the 618 had a 4 point mount . IMO the 3 point mount was a very good idea . You can't get bed twist with a 3 point mount .

Mark .

Mark .