- Joined

- Jan 20, 2016

- Messages

- 602

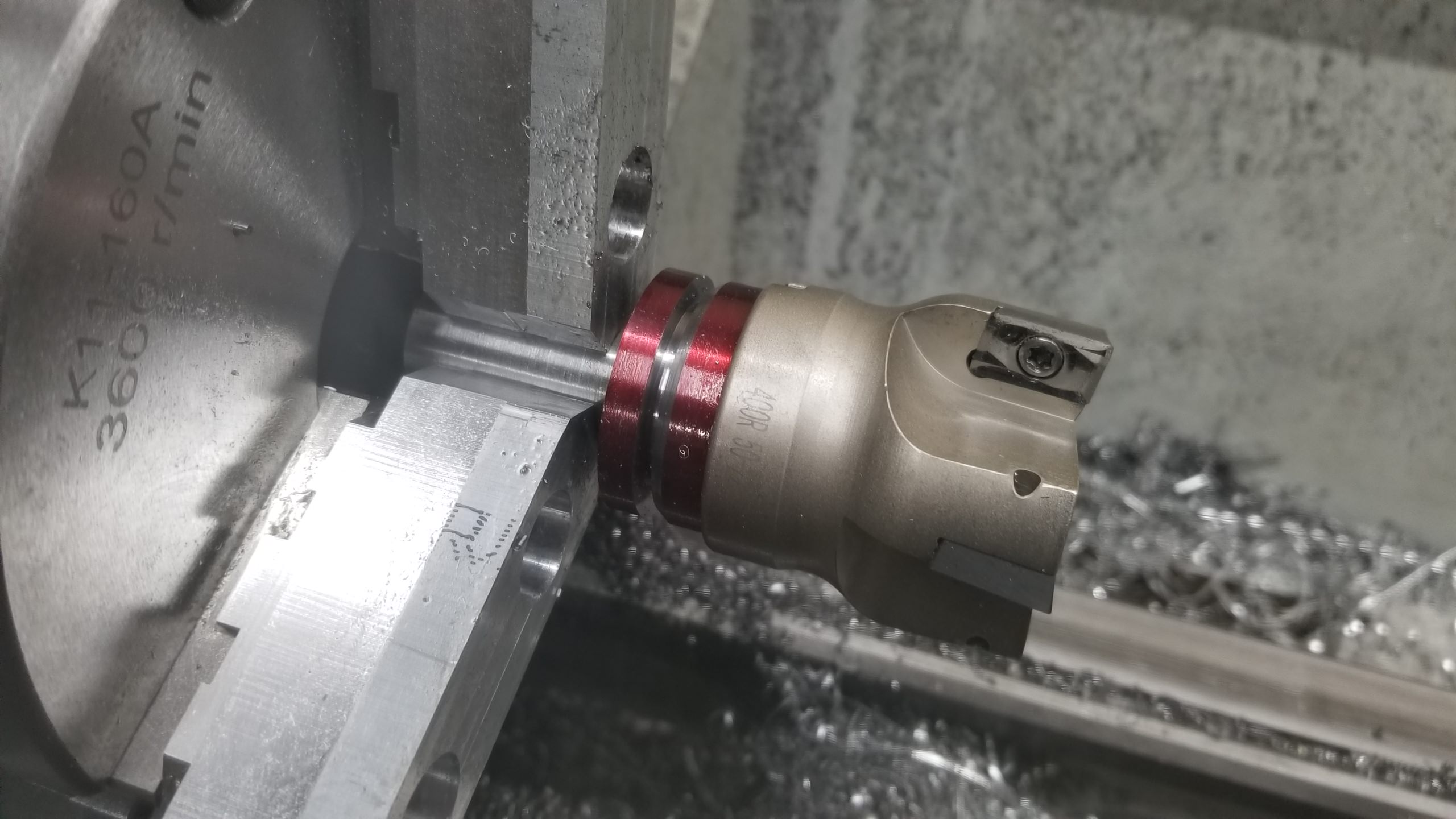

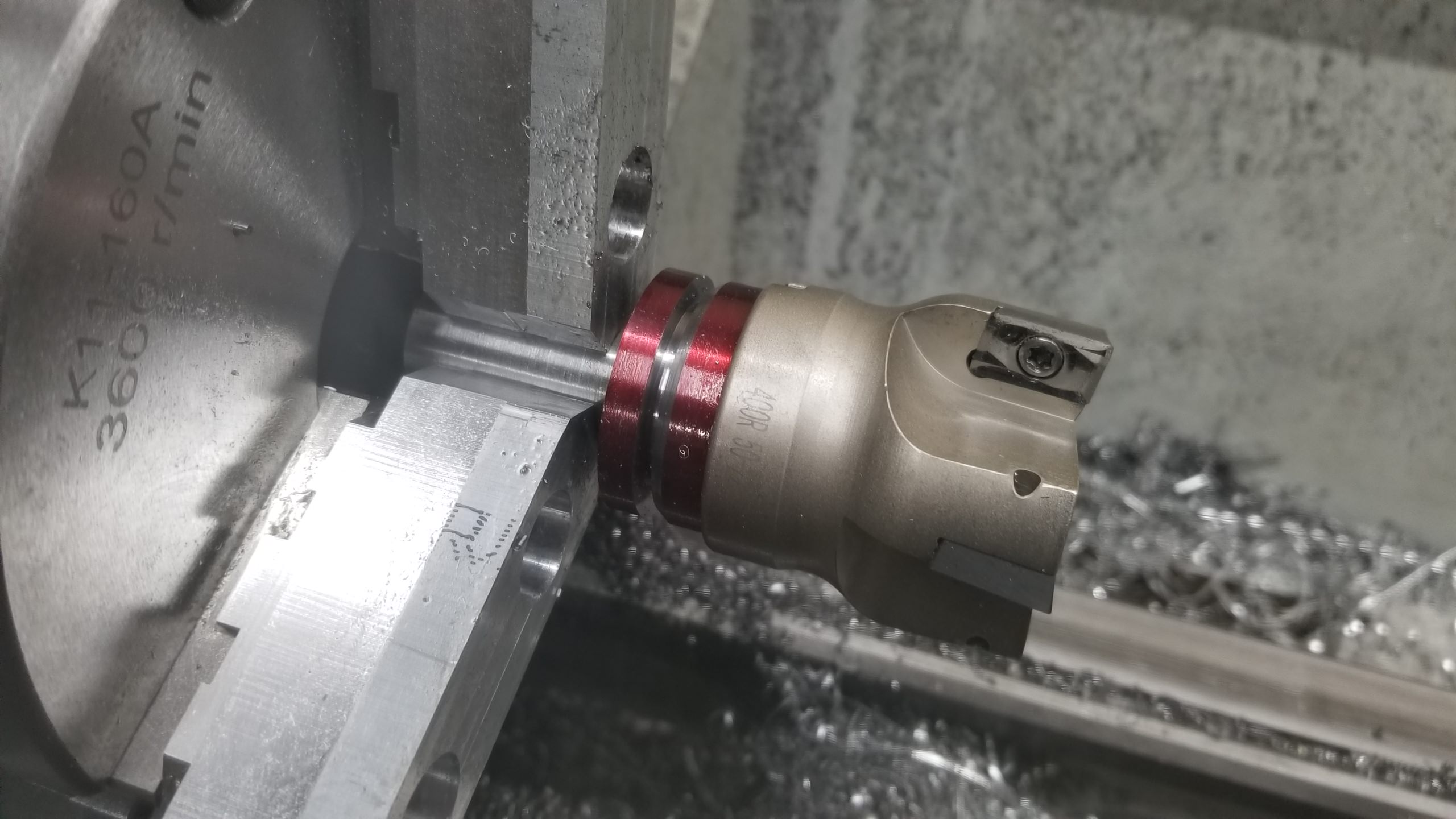

I tried one of those $25 ebay face mills from China and it is about what you would expect. Does it work? Yea sorta. Does it work well? Ehhhhhhh. It will remove material, but there is no way the inserts are at the same height. The finish is fine, but you can clearly see it wobbling. I wouldn't recommend, but for a $25 face mill, I am happy it makes a cut without exploding. This is the only picture I can find of the one I got, but I would recommend a fly cutter as well. A good face mill will be a bit more.