- Joined

- May 18, 2015

- Messages

- 231

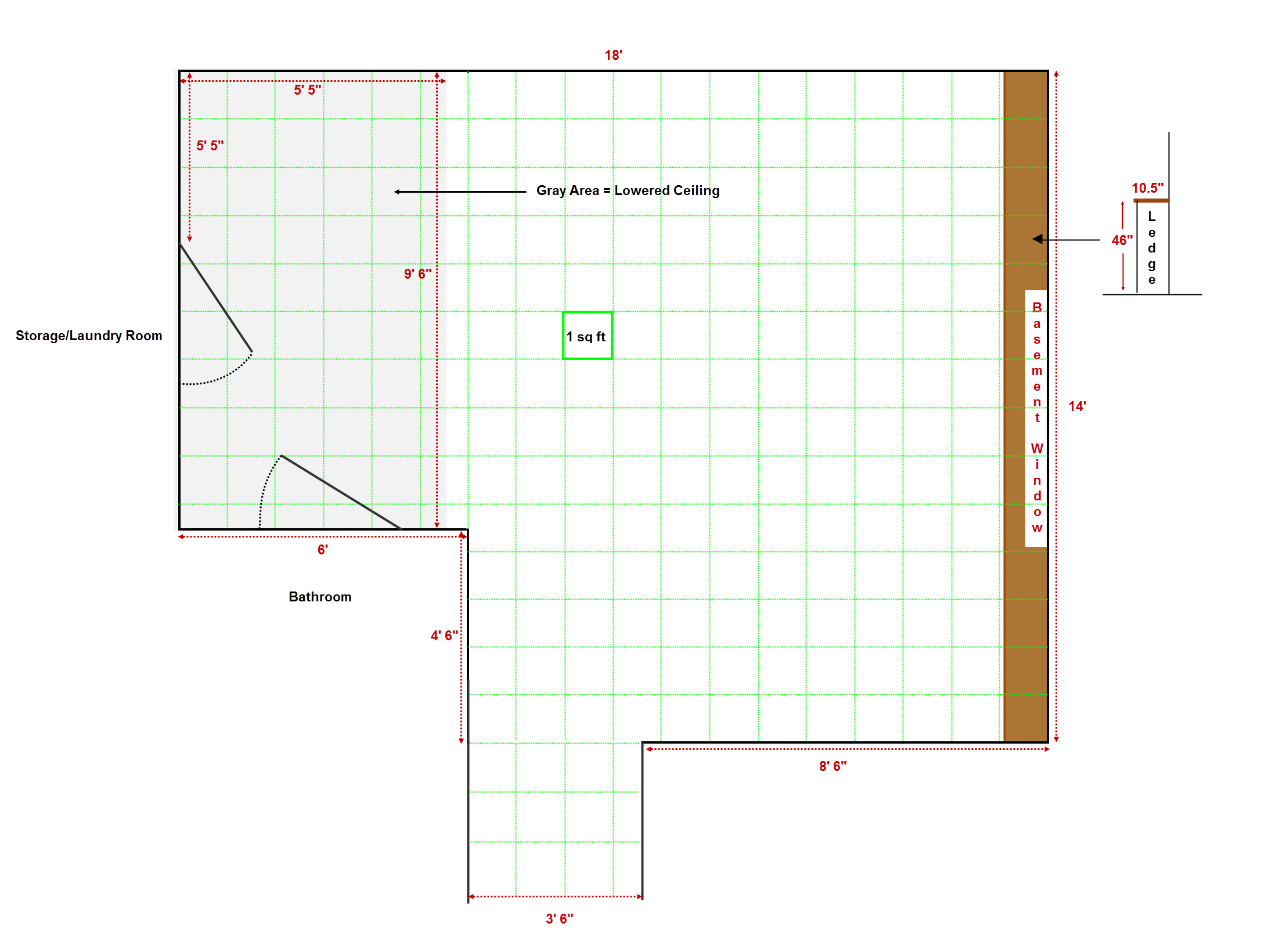

Here is the floor area

Not really. Generally called a "manufacturing cell". Park the tools in close proximity to maximize productivity. I have a 1000 sq ft garage (and no cars in it, of course), but my lathe and mill are about 5 ft apart facing each other, with a workbench down the side between the two.So if the room was twice that size wouldn't you want to spread everything out more?