- Joined

- Aug 6, 2015

- Messages

- 3,886

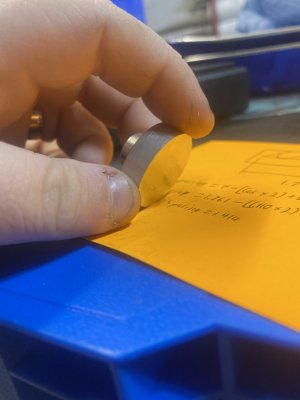

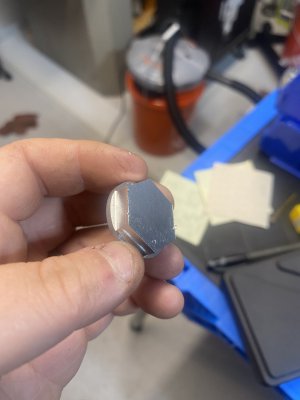

Got the 4 Flute, 90 Degrees Profile Angle carbide end mill and made the cut missing…

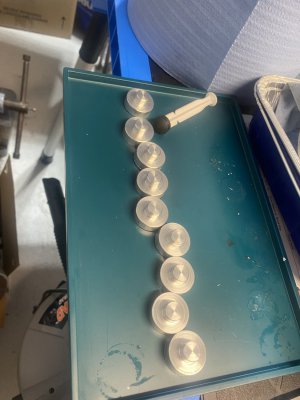

So now the vise milling work is done… will take it apart and paint…

On to finishing the base/mount…

Edit: To avoid a post... this one I painted hammered green... I will use it on the bigger drill press. I will make a second one that I will paint to match the Walter-Turner drill press...

Last edited: