- Joined

- Jan 25, 2015

- Messages

- 2,558

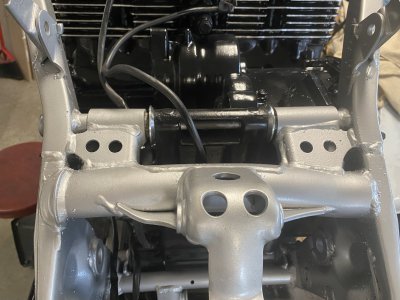

trying to figure out what I've done wrong with teh rear upper engine mount.

Before:

If you zoom in, you can see the bolt pulls two buskings into the boss on the engine. The bushings are tight to the frame and tight to the engine boss.

All I've done is pain tht eframe and engine and upon reassembly, discovered this:

Somehow, it appears the frame has "spread". Or a more likely scenario is I'm either missing a part (nothing on a parts breakdown or in the service manual) or I'm assembling it wrong.

I gotta figure it's something I'm doing wrong. There's no way the bolt would pull the frame rails together (it's heavily braced right in that area) and looking at other pics off the net shows the bushings tight to the frame and engine boss:

I'll figure it out, just a bit stumped right now.

Worse comes to worse I'll either make a couple spacers or just machine out some new bushings. But I'm reluctant to do so without first figuring out why it's changed from a simple remove/install....

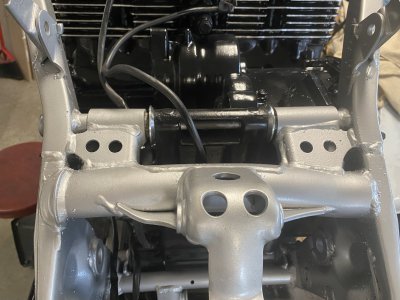

Before:

If you zoom in, you can see the bolt pulls two buskings into the boss on the engine. The bushings are tight to the frame and tight to the engine boss.

All I've done is pain tht eframe and engine and upon reassembly, discovered this:

Somehow, it appears the frame has "spread". Or a more likely scenario is I'm either missing a part (nothing on a parts breakdown or in the service manual) or I'm assembling it wrong.

I gotta figure it's something I'm doing wrong. There's no way the bolt would pull the frame rails together (it's heavily braced right in that area) and looking at other pics off the net shows the bushings tight to the frame and engine boss:

I'll figure it out, just a bit stumped right now.

Worse comes to worse I'll either make a couple spacers or just machine out some new bushings. But I'm reluctant to do so without first figuring out why it's changed from a simple remove/install....

Last edited: