-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

- Thread starter wachuko

- Start date

Copying is the finest form of flattery.

It was probably this thread were someone showed a tool post mounted guard. I thought what a fantastic idea so I ordered a generic NOGA articulating arm, it arrived yesterday. Works really well.

The window in the factory guard is great if you want to watch the chuck rotate, not so great for watching the "cut"

It was probably this thread were someone showed a tool post mounted guard. I thought what a fantastic idea so I ordered a generic NOGA articulating arm, it arrived yesterday. Works really well.

The window in the factory guard is great if you want to watch the chuck rotate, not so great for watching the "cut"

Attachments

- Joined

- Nov 24, 2014

- Messages

- 3,179

@slow-poke

In the picture, it looks like you've motorized your compound slide.

Did you post a thread on that work? Link?

If not, please tell/show us what's going on there.

In the picture, it looks like you've motorized your compound slide.

Did you post a thread on that work? Link?

If not, please tell/show us what's going on there.

- Joined

- May 3, 2017

- Messages

- 1,997

Probably got that from me. And I am, indeed, flattered.Copying is the finest form of flattery.

It was probably this thread were someone showed a tool post mounted guard. I thought what a fantastic idea so I ordered a generic NOGA articulating arm, it arrived yesterday. Works really well.

The window in the factory guard is great if you want to watch the chuck rotate, not so great for watching the "cut"

This thread, December 12:

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

Water or diesel fuel, dependent of the need.

www.hobby-machinist.com

www.hobby-machinist.com

I took mine off for the first time this past week because of a project I was doing. BIG difference in chip-flinging nuisance. Yours looks great!

Regards

- Joined

- Jul 14, 2017

- Messages

- 2,448

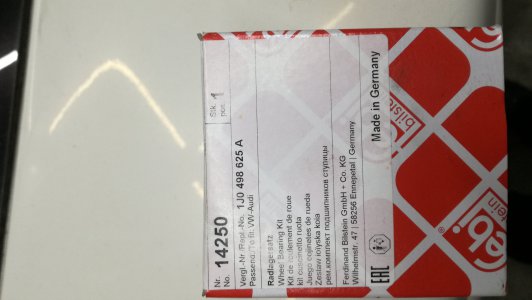

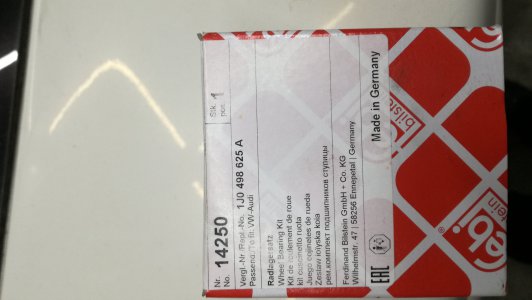

Today after work i had to fix the white elephant No:1, yes yesterday was No:2 today number 1. It developed a very very loud wheel bearing noise and rumble. On my way form work i bought a new bearing. Getting the spindle out wasn't easy but pressing out the bearing out was even harder, its been very hot and whoever was last to change it beat it to death, when i got it out i found is the sam make as the new one and is from 2015. With the new bearing installed i had to cut out some ropes and debris from the axle and assembly it, the thickents of the brake pads was a big suprase, i changed the pads about 8-10000 km and they are at 2mm also the disk and a big lip. It was past midnight so i assemble it to be used tomorrow, and i'll change the brakes when i buy parts. Changing a press in wheel bearing with basic hand tools in less than 2 hours on the floor was something i used to do but today it took me almost double that. I was careful not to overstress my back after the jump i had couple of days ago.

- Joined

- Dec 20, 2021

- Messages

- 879

So, been looking for a Harig punch grinder for a while. Just couldn't manage to find one for a good price. Also been watching the cheapo chinese punch grinders. Some have been getting good reviews. Well, now there's a rash of units that look like absolute junk for less money. Bit the bullet and bought one of the last ones that looked well made.

Free shipping, and a 30 days return window, how bad can it be? It finally showed up. Left it in the box to warm for a day and started looking at it yesterday. Was surprised to see it has a rack/pinion drive for the V block. Fit and finish are actually very nice. Grinding looks really good, it operates smoothly. Until I tried to move the V block. It was tight, which is actually what I was hoping for. That I can hone to fit, loose is a much bigger problem. Spent a few minutes honing the sides of the V block down (same on each side) on a 600 grid diamond plate. Got it to move real nice.

Tonight is the moment of truth. Throw it on the surface plate and start checking it out. Big concern is the v block squareness, and how well its centered (esp. considering I honed the sides). Well, let's just say it won't be going back.

"Left to Right" (90 to -90) it appears to be within a fraction of a tenth. Dialed in, the runout on a carbide endmill appears to be a tenth. But honestly I think that might be the endmill. Some of the runout seems to move a when rotating the endmill. Clamping pressure might be bowing it, I think it's slighty tapered, and other oddness might be going on. In any case, I'm having trouble finding anything wrong with this thing. So, yeah very pleased. Everything that needs to be good is pretty darn good. (Maybe not quite as good as a harig, but it's probably better than me on the surface grinder! lol)

The T slot nut to hold the V block in place is a little rough. I'll probably surface grind that, and maybe have to hone the T slot face just a little bit. Might lap the nut to the T slot. Probably replace the few screws with quality hardware, but overall for the price Zero complaints.

Then, someone handed me a bag 'o goodies today. Looks like a Michelson Optical interferometer. Bummer is it's missing two very fine pitch screws on the fixed mirror. Those may be hard to find, or even make! #6-80 or something stupid.

Free shipping, and a 30 days return window, how bad can it be? It finally showed up. Left it in the box to warm for a day and started looking at it yesterday. Was surprised to see it has a rack/pinion drive for the V block. Fit and finish are actually very nice. Grinding looks really good, it operates smoothly. Until I tried to move the V block. It was tight, which is actually what I was hoping for. That I can hone to fit, loose is a much bigger problem. Spent a few minutes honing the sides of the V block down (same on each side) on a 600 grid diamond plate. Got it to move real nice.

Tonight is the moment of truth. Throw it on the surface plate and start checking it out. Big concern is the v block squareness, and how well its centered (esp. considering I honed the sides). Well, let's just say it won't be going back.

"Left to Right" (90 to -90) it appears to be within a fraction of a tenth. Dialed in, the runout on a carbide endmill appears to be a tenth. But honestly I think that might be the endmill. Some of the runout seems to move a when rotating the endmill. Clamping pressure might be bowing it, I think it's slighty tapered, and other oddness might be going on. In any case, I'm having trouble finding anything wrong with this thing. So, yeah very pleased. Everything that needs to be good is pretty darn good. (Maybe not quite as good as a harig, but it's probably better than me on the surface grinder! lol)

The T slot nut to hold the V block in place is a little rough. I'll probably surface grind that, and maybe have to hone the T slot face just a little bit. Might lap the nut to the T slot. Probably replace the few screws with quality hardware, but overall for the price Zero complaints.

Then, someone handed me a bag 'o goodies today. Looks like a Michelson Optical interferometer. Bummer is it's missing two very fine pitch screws on the fixed mirror. Those may be hard to find, or even make! #6-80 or something stupid.

- Joined

- Dec 6, 2015

- Messages

- 810

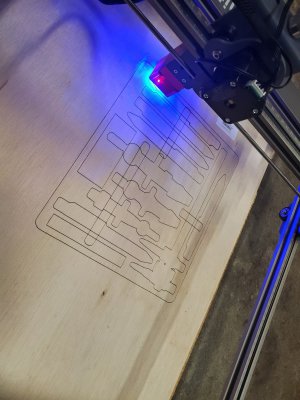

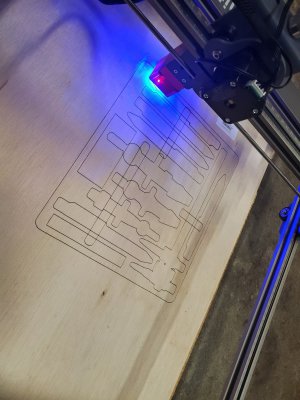

I used a laser engraver to cut myself a new box out of 1/4" plywood and glue it together. It should hold my rOtring pen/pencil (and my other drafting pencils).

I still need to sand and stain, and then add some felt liners to the cavities before I can install latches and hinges. I do need to remove rust from some old compasses and polish things up, too, but I think it will work just fine.

I'm excited for the possibilities this opens up.

I still need to sand and stain, and then add some felt liners to the cavities before I can install latches and hinges. I do need to remove rust from some old compasses and polish things up, too, but I think it will work just fine.

I'm excited for the possibilities this opens up.

- Joined

- Apr 23, 2018

- Messages

- 6,557

Don't ask me why I needed to use this ridiculous S&D bit, but it did what it had to and cut okay for having such a reduced shank once I hand sharpened it. I started out using my Albrecht because it was in the drill press and I was lazy. I quickly came to my better senses decided to use a bigger chuck, so I go the 3/4" keyed chuck out. I have a few decent Jacobs chucks, but I've been a fan of them since never. One of the things I don't like is the burrs on the shank that Jacobs chucks seem to leave. I took the picture after I removed the bit and kinda chuckled about it, because I don't know any way to stop it from happening. Yeah, it was tight, you think I'm not gonna instinctively reef on the chuck key with a 1-1/2" bit? Anyway, burrs aren't really a thing with self-tightening chucks. Those just self-tighten. That's a different thing. An Albrecht chuck key isn't made by Albrecht at all, it's a Ridgid #2 strap wrench.