- Joined

- Apr 16, 2019

- Messages

- 745

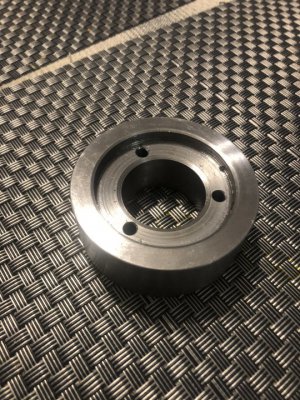

Like most members we start one project but need another to get the first one done . My cross slide screw was worn on my 5914 lathe , running the carriage in exposed the nasty looking threads , Another member on HM did a repair on his by getting a length of 5/8”-10 LH and mating to his . Ordered it last summer but was putting it off ,we’ll time has come to get going . Needing to machine the new threaded rod thought this would be a good time to make a spindle spider , my lathe has 3 taped 10-32 holes on the end of the spindle . I found a scrap that would make a nice spider . I counter bored it tried out the dividing head for the first time to drill and counter bore for the socket head cap screws . I was hoping to use 4 screws to hold work pieces . My cardboard template doesn’t give me any hope so unless someone has another way I’ll just use three screws .