- Joined

- Oct 14, 2013

- Messages

- 987

What do you think about your Delta surface grinder? Does it do work that looks as good as the grinder looks?

Sent from my SM-S911U using Tapatalk

Sent from my SM-S911U using Tapatalk

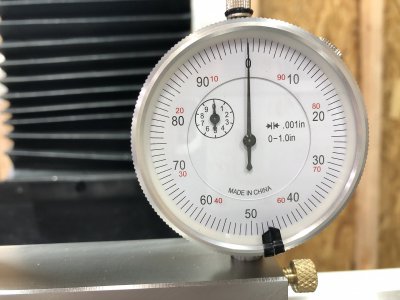

Well you know it can. It was a learning curve. So what do I think about it? I think it's too small to do big work and really you need to grind with misting or flood coolant and there is no way to catch it. I made a tray but it's not good enough. I made it out of aluminum and really it would have been better if a copper or stainless so I could solder a drain to it, I am thinking about redoing it. For my basement it makes sense because it was easy enough to get down, although the main base not the legs is probably about 300 -400 lbs. They call it a tool maker but I'm not sure why really doesn't have the proper geometry to be a tool grinder. There is a table they sell with it but it's very hard to find an expensive. If you want to hear more let me knowWhat do you think about your Delta surface grinder? Does it do work that looks as good as the grinder looks?

Sent from my SM-S911U using Tapatalk

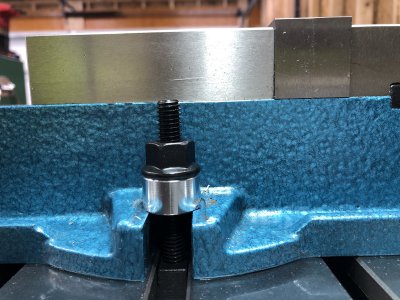

Nice job on the clamps. Everything need not cost $$$. Nice to have a few gals on the forum again. Mike

Thank you! My dad was really good at telling me that I can't do the things that I can do. I found at a young age that if you have the right tools you can learn to do anythingNice job on the clamps. Everything need not cost $$$. Nice to have a few gals on the forum again. Mike

I hope you had a cast iron skillet with you....

Bass.....what kind of fish is that?

It looks similar to the jade perch in my aquaponics system except for the large mouth.