- Joined

- Sep 2, 2013

- Messages

- 5,100

Curious why you would want a slip fit for the bearing i.d.. Normally I would think you would want a press fit for a non tapered bearing. Mike

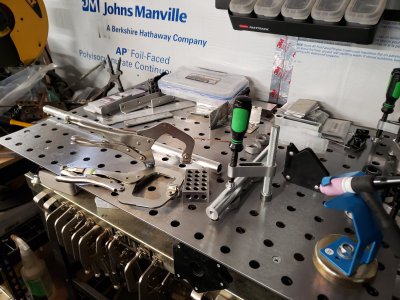

Little more progress on the crane. This simple part took WAY too long. Precision bored holes in the angle (OK, CNC milled), turned bearing holders with a shoulder press fit into the angle, and slip fit for the bearing.

The big 4 stroke never gets used as it is too big to haul to NY . Only time it gets used is at my yard sales these days to power up tools and compressor .

The big 4 stroke never gets used as it is too big to haul to NY . Only time it gets used is at my yard sales these days to power up tools and compressor .