- Joined

- Dec 23, 2019

- Messages

- 122

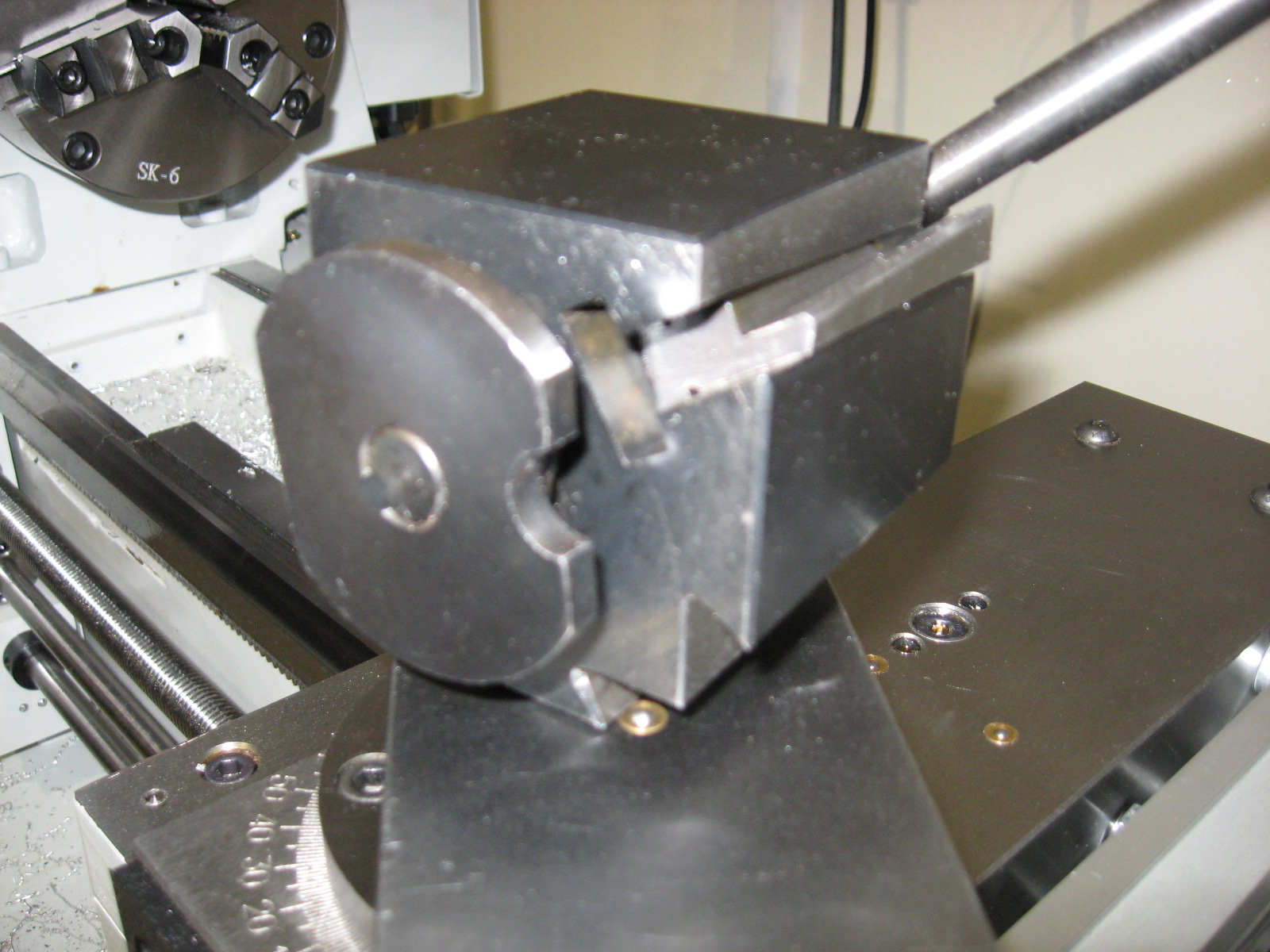

Received this QCTP with my PM1340GT lathe. A little concerned about the attaching base not being the size and shape of the tool post. A lot less contact on the compound that has me wondering about uneven wear/damage to the compound over time. I dont have a mill, or I'd build a new base. Is this a commonly seen type of attaching base?