Also did a quick and dirty rack my welding table to hang my grinders.

I did the same thing the other day for my grinding bench, along with a piece of muffler tube for my heat gun.

Also did a quick and dirty rack my welding table to hang my grinders.

She goes through steel and aluminum like butter at 50rpm, I even have a spare blade

matthewsx , A friend of my has the same saw slow turning HSS blade, when the blade gets dull it starts to snap the roll pin in the spindle, i'll advise use it for softer materials.

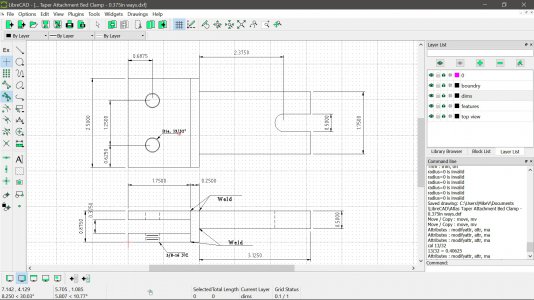

What you have built is called a mandoline, yes they are quite dangerous but you can build a pusher for it pretty easy.Wanted to make a batch of sour kraut but hate cutting up the cabbage so built a shredder.

The body is 1/2 inch poly with 3/4 for the sides. The knife was an old straight edge, think its ferritic stainless, seams really tough and took a beautiful edge.

View attachment 322811

Will reduce a head of cabbage to shreds in about a minute. Way faster than a knife, but it would love to reduce a finger too.

View attachment 322813

Also made a rammer to pack it into the pail.

View attachment 322814

Should have a batch in about a month.

Greg