- Joined

- Dec 3, 2015

- Messages

- 243

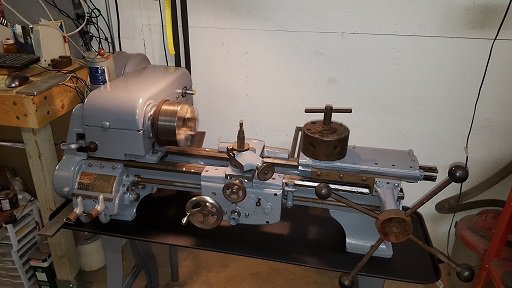

OK, the hole in the box is not the issue, the entire box itself needs to move towards you in the photo...Look at the gasket and you will see how much it has to move... it can't be rotated because that then causes a misalignment of the pulley and housing on the other side...

Last edited: