Every floor in my house is heated with electric floor heat as a supplement to our heat pump (Natural gas is not available in our neighborhood). I have used 2 different electric floor heat technologies depending on the type of floor.

Electric cable heat:

Over 10 years ago during my kitchen renovation I added this electric cable heat system to my kitchen floor.

1) Snaked the cable over my plywood subfloor and attached it with

cable staples.

2) Covered the cables with a mortar compatible fiberglass mesh.

3) Thoroughly covered the plywood subfloor, cable and fiberglass mesh with a mortar bonding agent.

4) Poured a modified self leveling compound strengthened with a latex add mix over the plywood, cable and mesh.

5) Installed a tile floor on top of the self leveling base.

This has worked perfectly and has given me NO problems in the past 10 years. We love the heated tile floor in the middle of the cold winters! Recently I had to remove a single tile for a project and the self leveling compound took an exorbitant amount of work to hammer and chisel through! I have read that an uncoupling membrane or cement board is needed to successfully install tile over a plywood subfloor... I disagree. I have installed this same system in 3 bathrooms and our slate tiled entry way over the years with equally excellent results.

You can buy this same cable already attached to the fiberglass matt from HomeDepot or Lowes for over 5x the price of ordering off of ebay. (Amazon didn't carry such things when I installed my kitchen tile floor).

https://www.ebay.com/itm/Electric-T...621939?hash=item3650c99433:g:GlAAAOSwsJRdJYN6

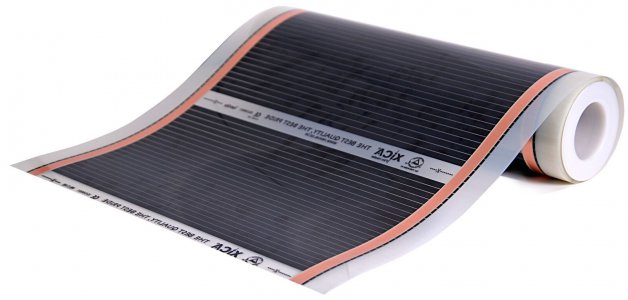

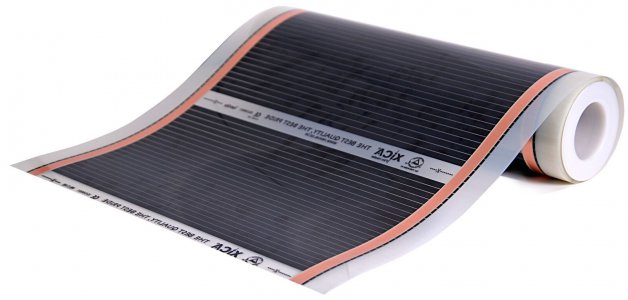

Carbon film:

Carbon film:

I have also used this carbon film under engineered wood flooring with excellent results. This system calls for using crimp clips to make the electrical contact with the copper contact stripes. Don't do that! Remove the thin layer of plastic covering the coper contact strip and solder the wire directly to the copper strip. It is very easy and makes a much thinner connection than the clip plus will be MUCH more secure and much less likely to have issues in the future. I have this system in 4 bedrooms and our great/living room. We are VERY pleased with this! The markup on this carbon film heat mat is even bigger than the cable heat above at the local home centers. (Yes, I ordered min from China and it is VERY well made!)

https://www.ebay.com/itm/Carbon-War...654694?hash=item53f7bd28e6:g:P8cAAOSw~y9ZBevu

I know the original question was about hot water radiant floor heat but you might consider using the electric cable heat as an alternative. I think the install would be much easier, the floor would maintain a more uniform temperature over the entire floor and the heat time would be considerably faster than the hot water systems I have lived with in the past. All of my research said that the electric cable heat is just as if not more reliable than hot water floor heat. The identical cable is often used in concrete walkways to eliminate the need for snow removal with an excellent track record of reliability! I wish I could figure out a way to put this cable heat over the eves under my soon to be installed roof so I don't have to pull snow off the roof to prevent ice dams!

If you do have natural gas available at your house I would choose a hot water floor heating system and a gas water heater over an electric floor heating system!