- Joined

- Dec 20, 2012

- Messages

- 9,422

Plunging with a center cutting end mill is a plunge cut. Plunging with a non-center cutting end mill requires you to drill a hole to clear the center of the hole before plunging with the end mill, in which case it is still called a plunge cut.

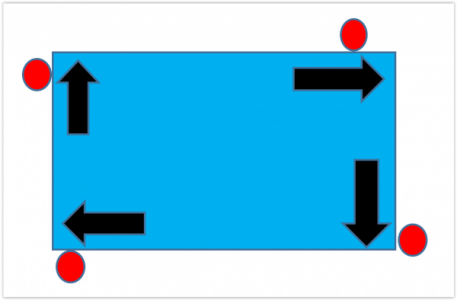

A slotting cut is called a slotting cut, whether you plunge the end mill in first or drop it into a pre-drilled hole to start the slot. If you are cutting the slot with both sides of the end mill at the same time then you are cutting "conventionally" on one side and "climb cutting" on the other side at the same time, and it doesn't have a name other than slot cutting.

If you are using an end mill to widen an existing slot then typically you would either climb or conventional cut each side, your choice. In a slot it is probably better to conventional mill it to reduce vibration if you have a light spindle or thin end mill or if the slot is deep for the diameter of the cutter.

A slotting cut is called a slotting cut, whether you plunge the end mill in first or drop it into a pre-drilled hole to start the slot. If you are cutting the slot with both sides of the end mill at the same time then you are cutting "conventionally" on one side and "climb cutting" on the other side at the same time, and it doesn't have a name other than slot cutting.

If you are using an end mill to widen an existing slot then typically you would either climb or conventional cut each side, your choice. In a slot it is probably better to conventional mill it to reduce vibration if you have a light spindle or thin end mill or if the slot is deep for the diameter of the cutter.