- Joined

- Mar 26, 2018

- Messages

- 8,407

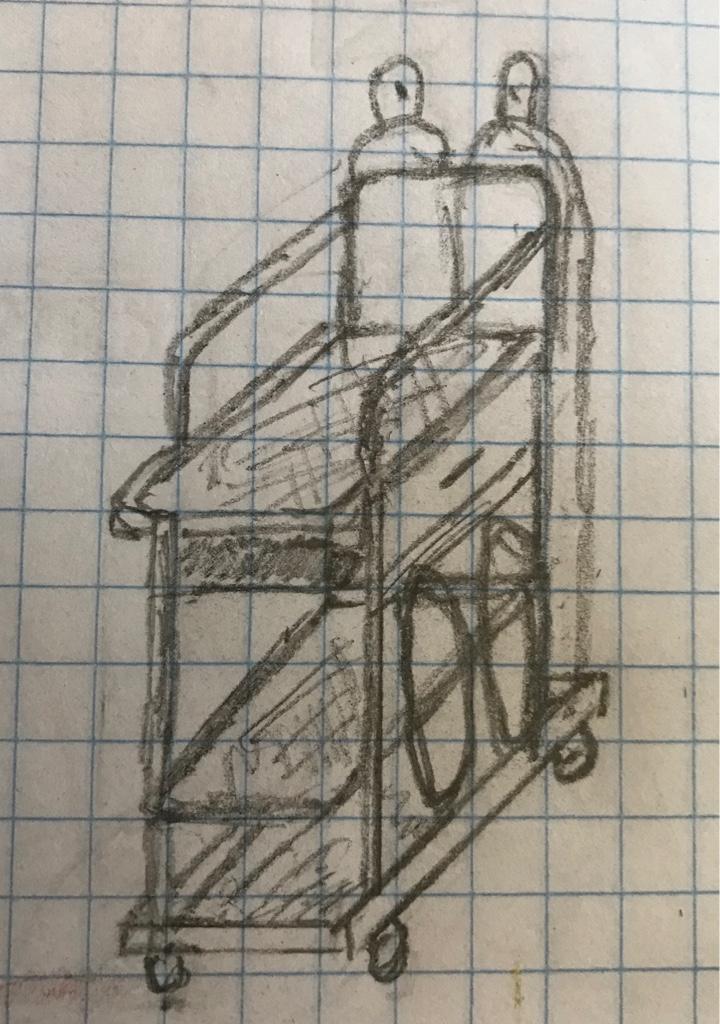

I built a nice cart for my TIG, MIG, Plasma and bottles.

I'm now thinking of placing the tanks in a corner and running tubing to the welders on my table shelf.

By doing this, I gain the floor space from losing the cart.

The jury is still out on this one.

I'm trying to figure out where to put the band saw.

I have the horizontal milling machine that I have only used once. (Ulma Doc donation) I could never get rid of it.

Small shops are us.

I'm now thinking of placing the tanks in a corner and running tubing to the welders on my table shelf.

By doing this, I gain the floor space from losing the cart.

The jury is still out on this one.

I'm trying to figure out where to put the band saw.

I have the horizontal milling machine that I have only used once. (Ulma Doc donation) I could never get rid of it.

Small shops are us.