- Joined

- Oct 16, 2019

- Messages

- 6,580

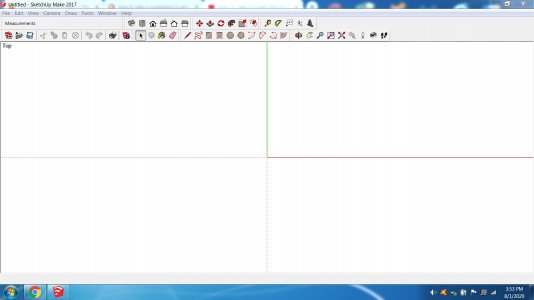

Did a quick sketchup drawing of your welding cart. This just a preliminary drawing. I can add more stuff later

View attachment 332102

Wow, that’s super decent of you @mickri!

Sent from my iPhone using Tapatalk

Did a quick sketchup drawing of your welding cart. This just a preliminary drawing. I can add more stuff later

View attachment 332102

Did a quick sketchup drawing of your welding cart. This just a preliminary drawing. I can add more stuff later

View attachment 332102

Very nice work. I tried to learn sketchup, but I just found it time-consuming since CAD isn't my strongsuit. One day......

I played with it yesterday and had good success following a tutorial.

I failed miserably at Fusion 360 but I think I can become functional at SketchUp.

Sent from my iPhone using Tapatalk

I would consider having the MIG on top, simply because you have to change the spool occasionally. I've never opened my TIG...Here’s one sketch, tanks at the back. TIG on top, drawer under that, then MIG and a space underneath for the foot pedal and other flotsam.

(It should be completely obvious that I failed out of art school)

Sent from my iPhone using Tapatalk

I spend maybe about 90 minutes on the drawing I posted. Could have done it much quicker if I hadn't made everything .060 thick. The trays and the drawer I drew as if I was starting with a flat sheet of .060 steel and thinking how it would get bend to form the tray or drawer. The framework is 1x1x.060 wall. Also everything is divided into groups. The casters are a group. The bottom and top trays are separate groups. The frame is a group. The drawer is a group. Using lots of groups makes it really easy to fix errors. For example. I made the drawer slightly too wide. Took seconds to narrower because it was its own group. If I hadn't made it in its own group I would have had to make changes to the frame.

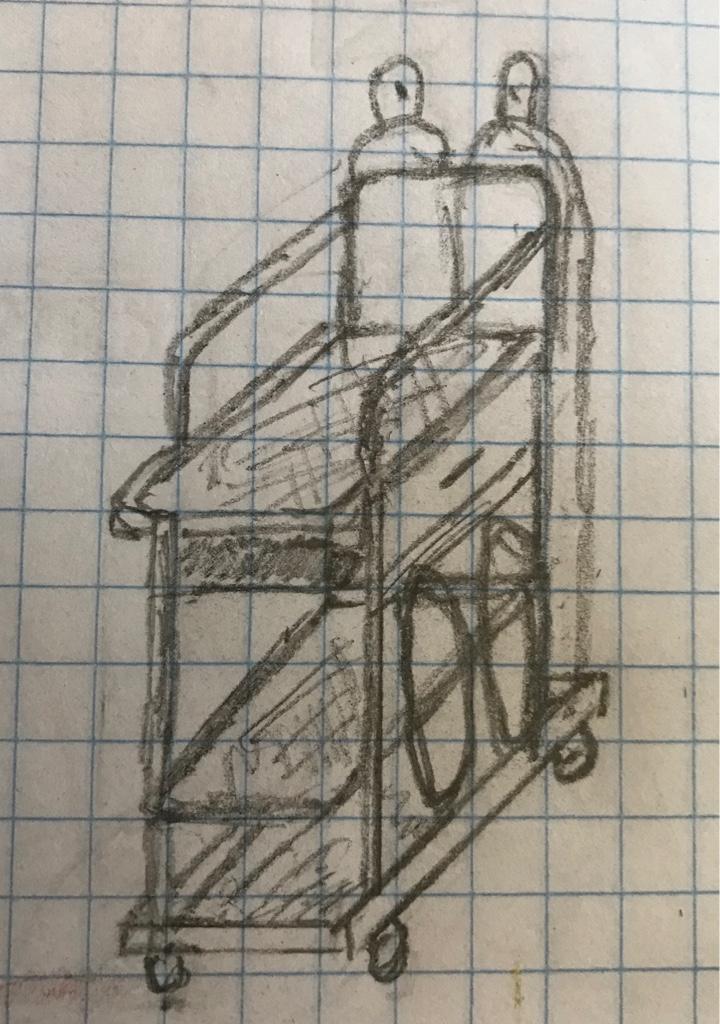

I don't like using a mouse. I am an excellent typist and any time my fingers leave the keyboard things really slow down. I use a laptop with both a touch pad and a small joystick to move the courser. I mostly use the touch pad. Here is a screen shot of how I have sketchup set up with the buttons I use the most. The only buttons I would like to add that I haven't been able to figure out how to add them are the "delete guides", "dimensions", "hide", and "unhide". I'll have to research how to make a custom toolbar someday.

View attachment 332214