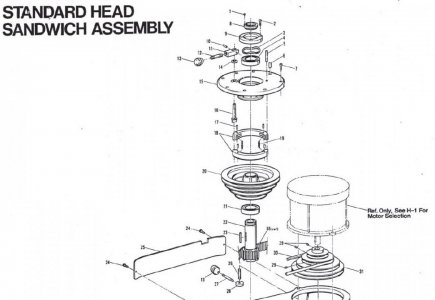

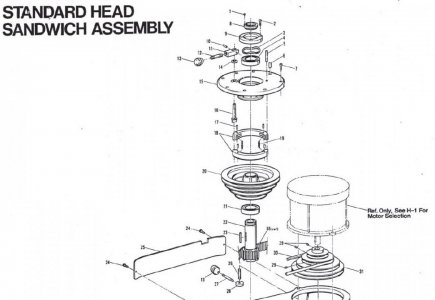

Okay, so here are the parts I want to replace. From this diagram, that would be 3, 4, and 21

(1) 880-067-004 - Wavey Washer. - it is fine, but since going in there, might as well replace for a new one

(1) 885-001-031 - Top Bearing

(1) 885-002-032 - Bottom Bearing

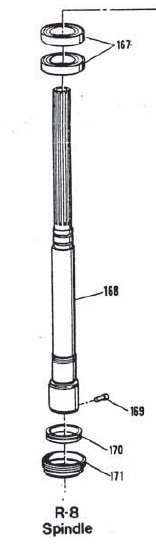

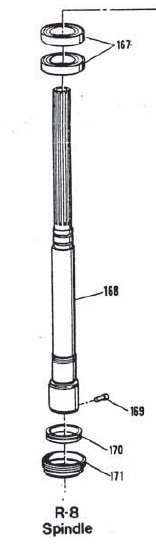

And from this diagram I would like to replace 169, 170, and 171

(2) - 100-002-975 - R8 Key - I really do not know how often these break/shear off... just want to have a couple of spares.

(1) 100-002-974 - R8 Ring - this is the bronze ring that retains the R8 key in place. It is fine... figured I would get a spare one as well.

(1) 000-200-007 - Lower Bearing Retainer R8 - this one is fine, but during the life of this machine someone took a monkey wrench to it instead of just using the correct tool... purely cosmetic, but I want to replace it anyway... again, the one there is fine... Maybe once I find out the price of this one, I will think that those marks are fine

.

And photos...

Here you can see the marks on that retainer nut...

And the brass ring that holds the R8 key from coming out...

R8 key