- Joined

- Oct 7, 2020

- Messages

- 2,115

Nice work Wachuko!

two things, the bearing cap, drill 2 new holes, don't try fixing those old holes.. they are of no valueI also removed the motor, belts, etc. Wanted to clean in there... it was all full of grease/oil... just nasty...

Here, take a look... before:

View attachment 393525

And after...

View attachment 393526

View attachment 393528

View attachment 393527

View attachment 393529

I will remove all this again for further cleaning and repainting it... but the task at hand was to just inspect everything and determine if the spindle bearings were in good condition. Glad to see that they were... So everything got assembled back.

View attachment 393531

Then rotated the head back in place. I took the tramming tool with me, but did not have a chance to use it... need to do that as well.

I still need to redo the oiling system... that will be next...

Took the cheap vise from the house in Orlando... eventually I want to get a Kurt DX6 vise... but this will do for now.

View attachment 393530

two things, the bearing cap, drill 2 new holes, don't try fixing those old holes.. they are of no value

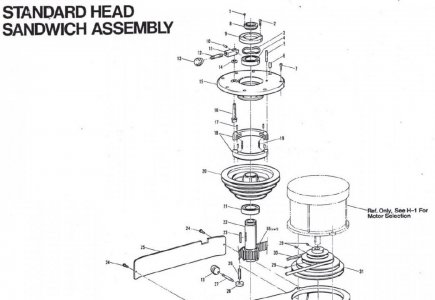

what's the plastic gear for in the top of the quill bore???? it does not look like it's fully engaging.

nice job so far.

you said they were quiet, why are you replacing them? If you want, take them out clean them in solvent, repack them using a high quality grease, maybe a molybdenum disulfide grease and reuse. If you start using it and it's giving you problems then replace the bearings.SOB!!! One of the bearings, the bottom one... US$104.25!!!! They do not have the top bearing...

(1) 880-067-004 (056-004-476 old #) - Wavey Washer - $15.70

(1) 885-001-031 - Top Bearing - Not in stock

(1) 885-002-032 - Bottom Bearing - $104.25 !!!!!!

(2) - 100-002-975 - R8 Key - $12.95 each

(1) 100-002-974 - R8 Ring - $21.25

(1) 000-200-007 - Lower Bearing Retainer R8 - $79.70

you said they were quiet, why are you replacing them? If you want, take them out clean them in solvent, repack them using a high quality grease, maybe a molybdenum disulfide grease and reuse. If you start using it and it's giving you problems then replace the bearings.

Looks like the only thing you really needed was the r8 key (maybe)

Measure those bearings, then get looking for a bearing supplier with a better price. I believe they're all standard sizes. I got several replacement bearings for my 847 from the auction site, and for a very reasonable price. These weren't the main spindle bearings, but were in the upper head. I did clean and repack a bunch that sounded fine. I used a good quality moly grease and was careful to get them spotlessly clean and not to overlube them. My spindle seems fine, so I'm leaving well enough alone there.

Mine has the 30 MMT spindle, BTW. It also has the variable speed head.

you said they were quiet, why are you replacing them? If you want, take them out clean them in solvent, repack them using a high quality grease, maybe a molybdenum disulfide grease and reuse. If you start using it and it's giving you problems then replace the bearings.

Looks like the only thing you really needed was the r8 key (maybe)