-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What Did You Buy Today?

- Thread starter darkzero

- Start date

- Joined

- Sep 24, 2017

- Messages

- 550

Looking niceI got me a new-to-me 6” 6-jaw chuck!

Seems the previous owner used it for turning graphite rods, so it was FILTHY. Took several hours and about a roll of shop towels to clean up. Good news is that graphite is super soft, so virtually zero wear on any of the innards.

Made in the Los Angeles area by QU Industrial; I’d never heard of the before, but it seems like a very high quality chuck. Hardened and ground everywhere.

It came with a back plate that fit my lathe, and has a Set-Tru feature and reversible jaws; I think I’ll get some pretty darn good use out of it!

View attachment 326431 View attachment 326432

Skickat från min I4312 via Tapatalk

- Joined

- Oct 4, 2016

- Messages

- 7,021

I have been practicing, and making new HSS tools on the 2 x 48 Jet belt sander. One of my difficulties is the back rake moves the belt over on the platen. If I track the belt over, without side load it will track over too close to the table. I thought to myself, self touch the back rake on the white AO wheels on the bench grinder. It actually did well, 8" wheel so not too much radius,,,,BUT when it was time to dress the wheel, POOF powder EVERY damn where. There is no port on the guard housing, so I put the vacuum right at the wheel opening, very little improvement, still a mess within 4' of the machine, so I said Hell no, not happening. I went to one of Mikey's spots, and ordered CBN wheels, and another light for my mill.

- Joined

- Nov 14, 2016

- Messages

- 3,002

I have been practicing, and making new HSS tools on the 2 x 48 Jet belt sander. One of my difficulties is the back rake moves the belt over on the platen. If I track the belt over, without side load it will track over too close to the table. I thought to myself, self touch the back rake on the white AO wheels on the bench grinder. It actually did well, 8" wheel so not too much radius,,,,BUT when it was time to dress the wheel, POOF powder EVERY damn where. There is no port on the guard housing, so I put the vacuum right at the wheel opening, very little improvement, still a mess within 4' of the machine, so I said Hell no, not happening. I went to one of Mikey's spots, and ordered CBN wheels, and another light for my mill.

I've come close to buying a set of these for tool grinding several times. I always come back to the money spent on the wheels would go a long ways toward a 2" belt sander. I'm interested to see what you think of them, and how you like grinding a tool on a CBN wheel vs your belt sander. It might help me overcome my indecision.

- Joined

- Nov 14, 2016

- Messages

- 3,002

I still like the belt, it's flat, and quick, I still need to mount the CBN wheels....

I'll wait, I'm patient.

Found this on eBay, now just get it off the trailer.

View attachment 326696View attachment 326696View attachment 326696

View attachment 326696View attachment 326696View attachment 326696

Wanted one of these for while, just have figure out how to get it off the trailer

View attachment 326695

Engine hoist?

- Joined

- Nov 14, 2016

- Messages

- 3,002

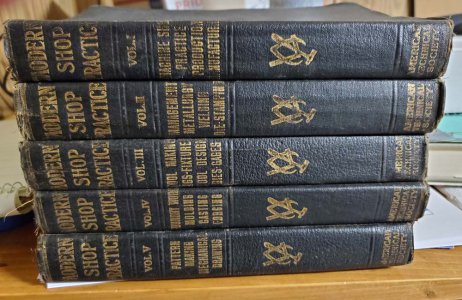

Printed in 1921 , 5 volumes of a 6 volume set, the missing volume covers machine drawing, auto work and an index. For a little less than $40 shipped these looked interesting. They are in nice shape with that great old book look and feel. I find old text books much more useful than books written for hobbyists.