I just set it on top of a bench that had a 2x4 top.Tell us about the concrete countertop. How has it held up as a workbench top? Thanks.

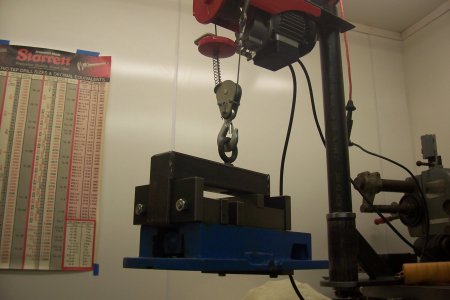

Since that photo, I’ve loaded it down with a vise, a bench motor, and my Gerstner box on a Kennedy mid-box. Hardly any room left

The top is an asbestos concrete that was surplus from Oak Ridge National Labs—it’s basically impervious to everything.

Note the HF lift cart next to it. I used that to lift it up high enough to slide it onto the bench.

Rick “drilled the vise holes wet while masked up” Denney