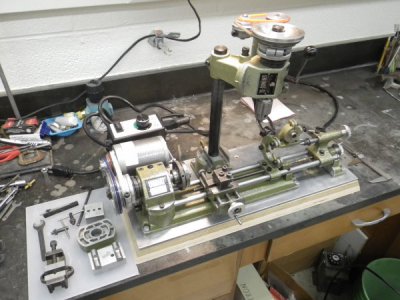

I started with the South Bend 9A (QCGB, power cross-feed etc) then got a a used Taig out of curiosity. Couldn't resist for $40

The Taig is very accurate, changing speeds is so easy you don't need a variable DC motor and it has a rack to enable faster carriage movement. The Sherline forces one to crank a 'leadscrew' to move the carriage which is very tedious. IMO, Sherline is way over-priced.

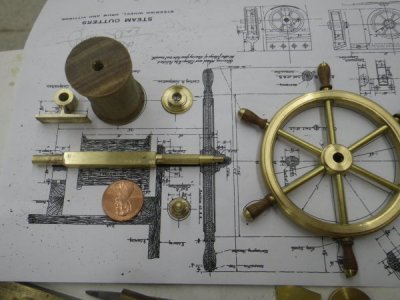

For those small parts you won't need power feed. I made a lead screw and crank for 'manual power feed' but rarely use it. The South Bend remains my main lathe but the Taig is handy for small stuff (like your fishing gear) and polishing.

Why not just get the basic Taig "kit", scrounge up any kind of motor and see how you like it? 1/4HP 1725RPM furnace motor is plenty.

Some links: http://www.deansphotographica.com/machining/projects/projects.html

http://www.modelengines.info/

http://www.cartertools.com/price.html

3mm fusible belt:

The Taig is very accurate, changing speeds is so easy you don't need a variable DC motor and it has a rack to enable faster carriage movement. The Sherline forces one to crank a 'leadscrew' to move the carriage which is very tedious. IMO, Sherline is way over-priced.

For those small parts you won't need power feed. I made a lead screw and crank for 'manual power feed' but rarely use it. The South Bend remains my main lathe but the Taig is handy for small stuff (like your fishing gear) and polishing.

Why not just get the basic Taig "kit", scrounge up any kind of motor and see how you like it? 1/4HP 1725RPM furnace motor is plenty.

Some links: http://www.deansphotographica.com/machining/projects/projects.html

http://www.modelengines.info/

http://www.cartertools.com/price.html

3mm fusible belt:

3M 2-8mm Transmission Belt Watchmaker Lathe Jewelers Belt Watchmakers PU | eBay

Note:Available at the required length. I send goods within 12 hours. Usually I will respond in 24 hours. Australia, United Kingdom.

www.ebay.com

Last edited: