-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Group Project: Dividing Head - The Build

- Thread starter Flyinfool

- Start date

- Joined

- Aug 13, 2020

- Messages

- 1,342

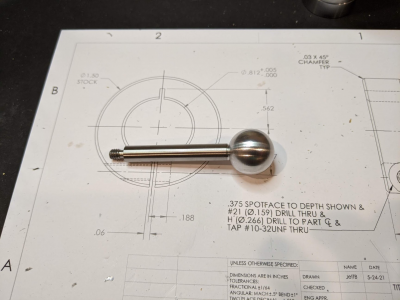

I got the "boring bar" done yesterday. Don't really know what else I'd call it. Put an indicator on it, and I get .020" TIR.

I have serious doubts that I will be able to hit 2.750"+/-.0005. I am certain that I will be able to get round holes of the exact same repeatable size. And, I am sure that the alignment between the base parts will be spot on.

I guess at this point, there is nothing to do but cut a test hole and see what I get.

The drawbar I made up from a bolt, an M12 socket head screw, and a piece of scrap cut-off.

I have serious doubts that I will be able to hit 2.750"+/-.0005. I am certain that I will be able to get round holes of the exact same repeatable size. And, I am sure that the alignment between the base parts will be spot on.

I guess at this point, there is nothing to do but cut a test hole and see what I get.

The drawbar I made up from a bolt, an M12 socket head screw, and a piece of scrap cut-off.

Attachments

Last edited:

- Joined

- Aug 13, 2020

- Messages

- 1,342

I couldn't stand not knowing. So, I spent my lunch cutting a test piece. Clamped a piece of 3/16" scrap plate to my QCTP, engaged the back gear, and set my lead screw to the slowest speed.

Because I had the part cantilevered out from the QCTP, it wanted to twist as it fed into the saw teeth, but I got that corrected about halfway through. I was still able to pick up a clean measurement of 2.560", and the finish on the cut is acceptably smooth.

Because I had the part cantilevered out from the QCTP, it wanted to twist as it fed into the saw teeth, but I got that corrected about halfway through. I was still able to pick up a clean measurement of 2.560", and the finish on the cut is acceptably smooth.

Last edited:

- Joined

- Aug 13, 2020

- Messages

- 1,342

I have a boring head, but I needed it to be at least 5" long. My goal was to mount the Auxiliary Base to the Main, bolt them down to the cross slide together, and then bore straight across to guarantee alignment. At lease as aligned head stock and bed.That is interesting. I assumed you were going to use a boring head. That would allow you to dial in the exact hole size. If you don't have one you may need to make one as a preliminary project!

Robert

Come to think of it, I can still make an adapter to this for my 2" boring head, and then open the hole up the last 15 thou. The adapter shouldn't take more than a hour or two to turn down. Then, I'd rough cut with the hole saw, and have a single pass to bring it to spec.

Wow, I guess I'm lucky the saw cut undersize.

- Joined

- Aug 3, 2017

- Messages

- 2,437

otherwise, there is always 'line boring', where you put the boring bar between centers, and it has an adjustable piece of HSS sticking out the side of the bar (near the middle). Then you bolt the part to the cross-slide and bore that way. I saw it once in a cylinder boring for a model steam engine.

- Joined

- Aug 13, 2020

- Messages

- 1,342

otherwise, there is always 'line boring', where you put the boring bar between centers, and it has an adjustable piece of HSS sticking out the side of the bar (near the middle). Then you bolt the part to the cross-slide and bore that way. I saw it once in a cylinder boring for a model steam engine.

Interesting. But, would it be possible to "dial in" the proper diameter?

- Joined

- Aug 3, 2017

- Messages

- 2,437

The kits I've seen put a screw behind the piece of HSS to advance it: http://www.hemingwaykits.com/acatalog/_Tidy__Between_Centres_Boring_Bar.htmlInteresting. But, would it be possible to "dial in" the proper diameter?

This is the build thread I saw of it: