- Joined

- May 14, 2019

- Messages

- 547

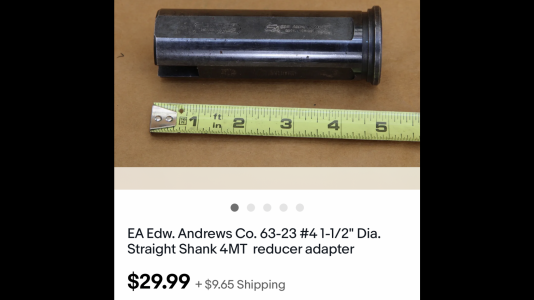

reamersWhat ya gettin!!!

drill chucks

screw machine drill bits ( number, letter index and for fractional)

keyseat cutters

carbide drills.

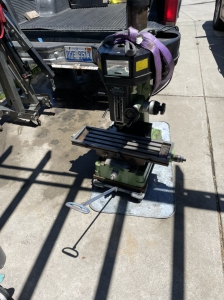

I had to call uncle before selling a kidney.

Matt was great to work with and very patient with all my beginner questions.

Good thing he is a long drive or I might have ended up with a dog as well.