4

4GSR

Forum Guest

Register Today

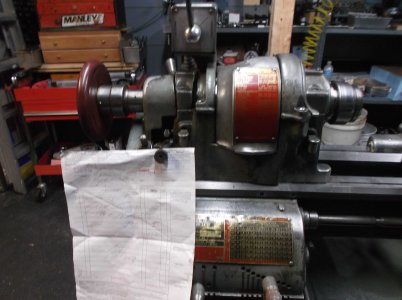

That's definitely not a gap bed lathe.

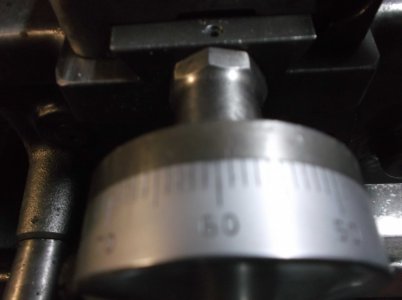

The tag for threading is not a newer tag. Also, the tag for the catalog size and length is a older tag, too.

Sent from my SAMSUNG-SM-G920A using Tapatalk

The tag for threading is not a newer tag. Also, the tag for the catalog size and length is a older tag, too.

Sent from my SAMSUNG-SM-G920A using Tapatalk